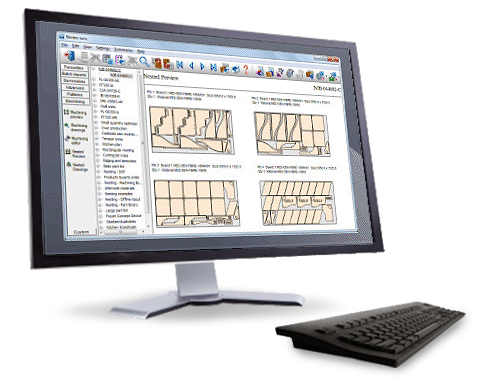

Nesting Optimiser

The Nesting optimiser will generate fast and efficient patterns for processing your rectangular and shaped parts and will download both routing and drilling instructions to your CNC router or nesting machine. Options for routing include 'Piece by piece', 'Stay down', 'Common edge' and provision for tabbing small parts.

Part drawings can be imported from layered 2D DXF files, the machining library or Woodwop MPR files. After nesting the CNC router software will generate and optimise the tool path for the nested patterns for export via DXF, MPR or other formats.

Example nested patterns in MPR (Homag), CIX (Biesse), XXL (SCM) and DXF (Universal) formats can be downloaded here.

Edging, Machining, Forms and Labels and the Parts library are included as standard.

Highlights

- Nesting software considerations include board margins, part separation, shape rotation, off-cut criteria, waste cuts and small part placement.

- Parts that need to be grain matched can be defined as a set using a template which is created using the machining editor.

- The rectangular nesting optimiser will determine the best size to pre-cut jumbo size boards that exceed the depth of the nesting table.

- Stay down routing - parts on a pattern are routed in a continuous operation extending tool life and saving cutting time.

- Tabs - the nesting optimiser can automatically leave tabs around small parts.

- The nested pattern editor allows last minute changes to pattern quantity and the ability to add further parts or new patterns.

- Where applicable horizontal machining and instructions for the back will be separated out and sent to an alternate specified path.

- NE will determine the most efficient sequence for routing the nested pattern with minimum tool changes, and can process small parts first.

- Common edge routing - edges of adjacent parts can be routed at the same time (when separated by the tool diameter).

- Board pre-cut - determines the best division of boards that are larger than the nesting table.

Magi-Cut has been an excellent addition to our company

Using Magi-Cut as our nesting software has helped increase production, reduce waste and increase efficiency from the moment we started using it. As a bespoke furniture company we needed to be able to produce one off designs as quickly as we could produce standard designs and using Magi-Cut we have been able to achieve this

G Baker - Neville Johnson

Printer friendly info