Optimising parameter to define how large offcuts are divided so that they can be processed correctly

This feature is available with the PO module

This parameter is used to define a preference on how large waste are divided into valid offcuts. There are several parameters that can be used to define whether a waste area is too large to be considered an off-cut: -

i) Maximum offcut dimension (on one side)

ii) Maximum offcut dimension (material flow direction)

iii) Maximum manual offcut dimensions and area

iv) Offcuts for automatic storage – Max length, Max width & Max area

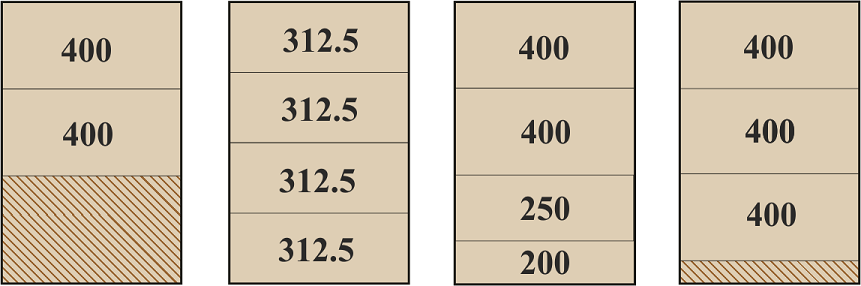

There are four preferences: -

None – the area is divided into two pieces, if these are not valid offcuts the area is divided into maxi-mum sized offcuts and a waste piece

Even offcuts – the waste area is divided into equal sized offcuts

Large offcuts – the area is divided into offcuts <= the maximum size

Maximum sized offcuts - the area is divided into maximum sized offcuts and a waste piece

e.g. Max offcut width = 400, Min offcut width = 200, saw blade = 5 and waste width = 1265.

In the example above the left most image is the old method of creating offcuts where the area was divided into two pieces. The next is the Even offcuts preference, the middle image is a Large offcuts preference and the right most image is a Maximum sized offcuts preference.

Notes

- Can also be set as a material parameter at both board and material level