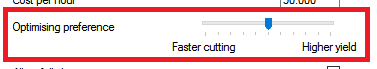

Allows users to configure their optimising preference for faster cutting or higher yield

This slider control allows users to configure their optimising preference for faster cutting or higher yield or a balance of the two. By default, the slider is positioned in the middle of the control and optimisations use the saw and board costs entered to minimise the total cost (saw and material) per unit area of parts produced.

Users who prefer patterns that can be cut faster (lower saw cost) should position the slider to the left and users who prefer patterns with a higher yield (lower material cost) should position the slider to the right.

As the slider is moved to the left, the optimiser uses a higher saw cost per hour to prefer solutions that are faster to process but this can reduce the overall yield and increase the overall material cost. The optimiser still minimises the total cost per unit area of parts produced but using a higher saw cost per hour.

As the slider is moved to the right, the optimiser increases the board cost rates to prefer higher yield solutions but this can increase the overall cutting time and saw cost. The optimiser still minimises the total cost per unit area of parts produced but using higher board cost rates.

The slider position only affects the costs used by the optimiser to evaluate patterns and solutions. The costs reported in Review runs are the actual saw and board costs entered.

This parameter is only available when optimisations are configured to Consider cutting time and the cost per hour is at least 0.01.

Notes

- Owing to the complexity and non-linear nature of the optimisation algorithms that sometimes individual results may not always follow the expected direction. Over a statistical sample of jobs then the effects of the slider will be seen clearly.

- This feature is only available with the PO Professional Optimiser module.