Nesting parameter to configure tongue and groove optimisations

Check the box to set tongue and groove mode

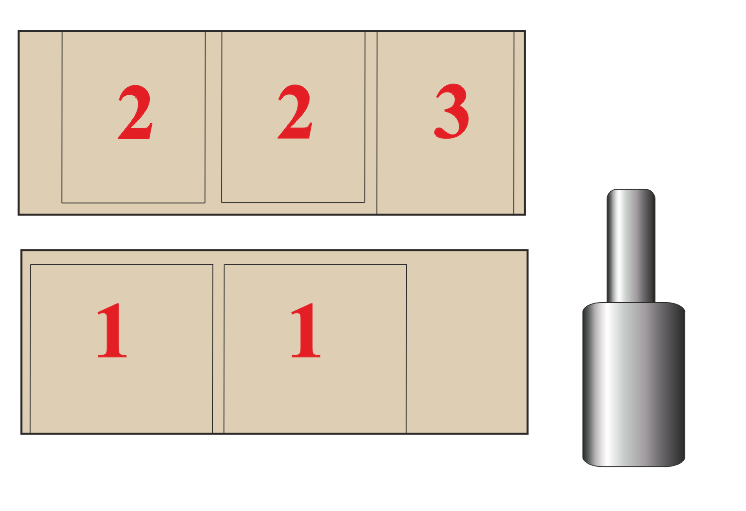

The ‘Tongue and groove’ information box is used to define part positions on the board (see the ‘Part’ group of information boxes). Parts can be configured to be at the tongue edge, groove edge or tongue and groove edges. Parts are positioned at the groove edge if no position is set.

1 = part with tongue edge

2 = part with groove edge

3 = part with tongue and groove edges

Parts with groove and tongue and groove edges are optimised together and are aligned to the board edge defined by the nesting origin parameter. Parts with a tongue edge are optimised in a separate set of patterns at the end of the run and are aligned to the opposite board edge

Parts with both a tongue and groove must be the same width as the board

Parts with a tongue edge or groove edge must be thinner than the board.

Notes

- Can also be set as a material parameter at material level

- Top and bottom board margins are ignored and assumed to be zero

- Parts with no grain set are assumed to be Y grain

- The number of pieces across the width of the sheet is limited to one.

- Board orientation settings are ignored and assumed to be lengthways

- No offcuts are produced from tongue and groove patterns