Analyse cutting requirements for best free cut

Some manufacturers offer a free cut when ordering a large quantity of boards; use the free cut analysis to help choose the most economic position for that cut.

It is best to judge the position of the free cut if by considering a large volume of cutting, for example, a single very large job, or a set of cutting list for several weeks or more.

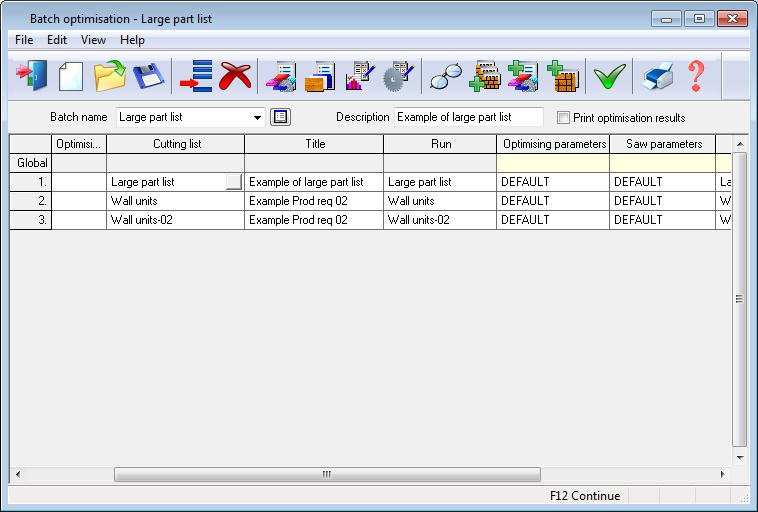

At the main menu:-

● Select: Review - Free cut analysis

The current batch is displayed (in the usual way)

- Check the batch and select 'Continue' to carry on with the transfer or optimisation.

● Select: File - Continue

or

Select

the Toolbar symbol

Select

the Toolbar symbol

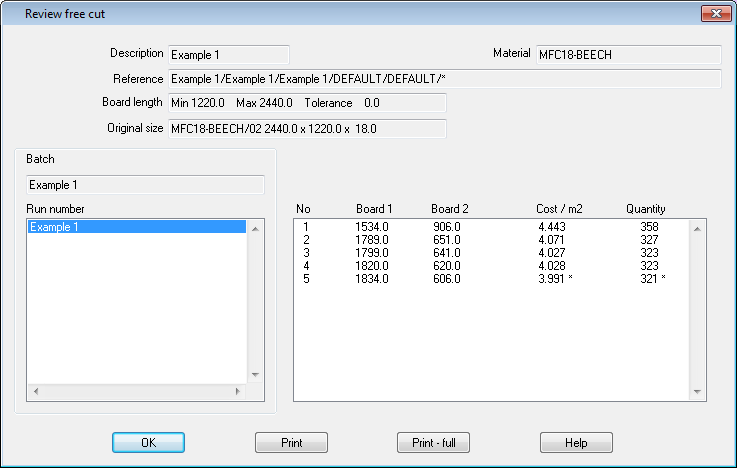

At the end of the analysis the program shows the results for each run.

The screen shows the most economic free cut positions for each run in the batch. There are up to 10 positions suggested for each run. The information shown is as follows:-

- part list title

- run number

- board material

- file references

- Min board length

- Max board length

- board length tolerance

- run number

- part list

- board length

- board width

- cost per unit number of boards

- area

There is one report for each run in the batch Choose PRINT to print the report for the current run. Choose FULL PRINT to print the results for all runs in the batch.

The Free cut position is displayed as Board 1 in the summary and the falling piece length is displayed as Board 2/ The * in the cost per unit area column indicates the result with the least cost. The * in the Number of boards column indicates the result with the least number of boards.

These two results are not always the same because, for example, the result that uses the least number of boards is not always the lowest cost result if the cutting time is expensive.

The results are provided only as a guide to good free cut positions for a range of data. Take care to use them as a guide and not a definite result because there are many other factors which may affect the choice of free cut position. The result is also very dependent on the data used for the analysis, so it is best to analyse the data for several weeks at a time to get a more useful view of the free cut position.

Remember also, that over the weeks the cutting requirements may change by cutting different jobs, or cutting jobs with significant changes to those which were originally analysed. Allow for this when selecting a free cut position.

The results of an analysis are stored in a file: 'runnumber.fhc'. This is automatically deleted when the run is deleted in the usual way.

- The board supplier's saw blade thickness is taken to be zero and their trims are assumed to be the same as the user's trims.

- No mixed materials are allowed

- There is a limit of 200 pieces in a large board.

- The results are rounded as follows:-

millimetres: 1mm

decimal inches: 0.1in

frac inches : 1/8in

The program assumes that the user's trims and blade thickness are to the same accuracy: thus a 3/16 in. trim would result in positions which are not rounded to 1/8in.If either the minimum or maximum length of the main piece is greater than the length of the large board, the lengths are constrained to length of the large board.

The program does not trap the error where the minimum length of the main piece is longer than the maximum length.

The optimising parameter Maximum open parts is not available with this analysis. Parts fitting some boards not other. All parts must fit all boards.

The batch checking does not consider the saw parameter Overall cutting length. Set the free cut parameters to cope with this instead.

Setup for Free Cut

Set the following Saw parameters:-

Free cut - length of main piece: min, max

Free cut: tolerance on large board

Review Free Cut

Recalls the last analysis for review