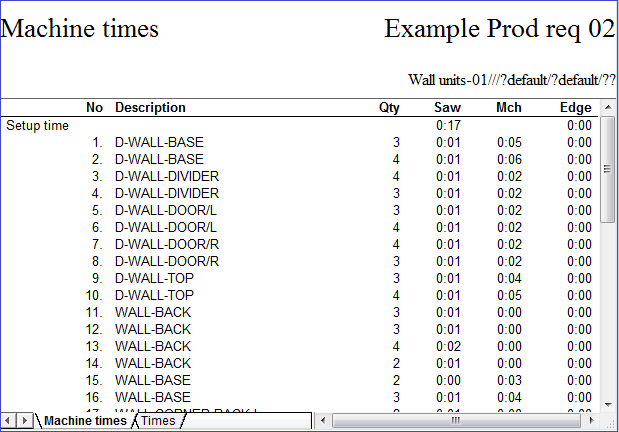

Summary of times for machining on a part

At the Review runs screen:-

● Select: Summaries - Machine times

or

![]() Select

the Toolbar option (Advanced)

Select

the Toolbar option (Advanced)

Shows the breakdown of times for each part on each machine or process in the factory.

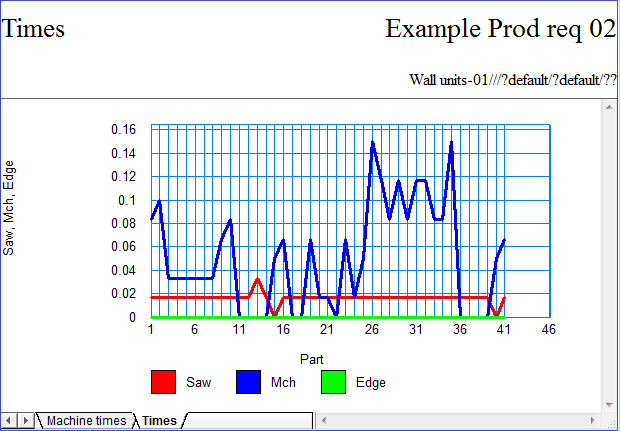

The tabs at the foot of the report can be used for custom graphs and charts..

Use the Navigation buttons, Summaries menu or Stacked toolbar to browse the summaries. Many Review Runs options are also available on the top Toolbar. As well as the default fields shown the report can be modified by removing or adding extra fields (see 'Settings - Report settings). A list of available fields for the report are shown.

adjust on-screen column and

row width

adjust on-screen column and

row width

![]() zoom display in / out

zoom display in / out

![]() print current report

print current report

![]() exit

exit

For full details of the on-screen options see help topic: Review runs screen

Notes

Cutting time - This is the total cutting time for each part. It is calculated as the total cutting time for the run apportioned between the parts, based on the part perimeters. A part perimeter is: 2 x (length + width). This means that a part that has twice the perimeter of another part will take twice as long to cut. This is a reasonable approximation of the cutting time per part.

Operation times - The operation times are standard times based on the standard time settings for each operation as specified in the information boxes for each part. In each case you specify a variable time (rate) and a fixed time for each operation. Up to 6 'User' times can be specified. These are not fixed and can be represent any operation or combination of operations that you choose.

The calculated times for sawing or machining etc. represent the actual operation time of each machine or operation, this is the time shown (for example) on the Management summary.

The time shown on the summary also takes account of the machine rate parameters (see 'Optimise parts'). The machine rates specify a usage for each machine or operation and so allow for down time and other inefficiencies.

For example if the calculated saw time from the Management summary is 7.2 hours and the machine rate for the saw is 85% the actual time needed is: 7.2 * 100/85 = 8.47 hrs.

These are the times for each machine or operation.

Mch - Total machining time per part. This is based on the machine instructions and the times for each instruction as specified in by the machine parameters.

Edge - The total edging time for each part. This is based on the length of edging for each part and the time for edging set in the Edging parameter list.

Operation times - User specified operation times

Total - Total time for each operation The bottom line shows the total time in minutes and seconds for each operation.

The Setup times are:-

Saw - bundle loading and setup time (time per bundle x no of bundles)

Edgebander - time to change material x no of materials in run

- cannot enter a fixed setup time per operation per run.