Custom information for the part list or part library for costing

For full costing of a job or production run all the costs and operations associated with a part have to be defined. This is done by setting up some extra Information boxes for the parts so that the correct information can specified for each operation for each part. Up to 20 custom operations can be set up. These custom operations are in addition to the predefined operations of: Saw, Machining, and Edgebanding operations. At the Main screen:-

● Select: Parameters - Information boxes

● Move to the next empty line in the grid

![]() Select

the List box

Select

the List box

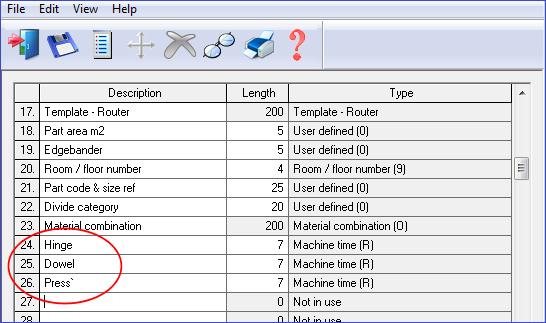

The screen shows the predefined information boxes.

● Expand the Costing item in the tree

● Select: Machine time (once for each user defined operation required)

The set up for Hinge, Dowel and Press is shown below

● Select Exit to exit and save changes

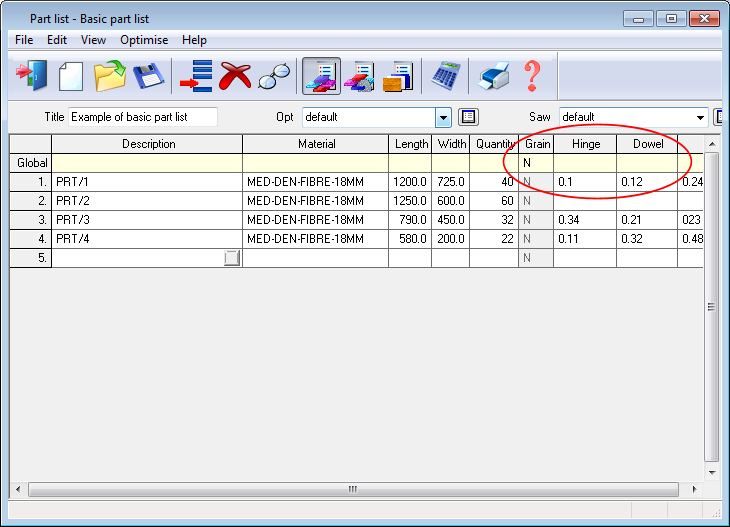

At the part list (for each part) enter the information for each operation. To do this enter in each machine time box the Variable time per part and the fixed time per part separated by a space.

Enter the VARIABLE time then the FIXED time in the information box. The two times should be separated by at least one space (blank) character. For example:-

Hinge : 1.2 18

This represents 1.2 seconds per part for hinge plate insertion with a fixed setup time of 18 seconds for setting up the program for this part.

The fixed time is applied once per part entry in the part list.

Note - cannot apply a fixed time to the operation itself on a per run or per day basis. If this is significant apportion it to the fixed time per part.

The times for each operation are stored in the pattern file.

The times that entered should not include any allowance for machine stoppages or inefficiencies. Instead set a machine usage percentage with for each machine with the 'machine rates' parameters to deal with downtime etc.

The machine times summary takes account of the machine rate parameters.