Steps to use grain match option

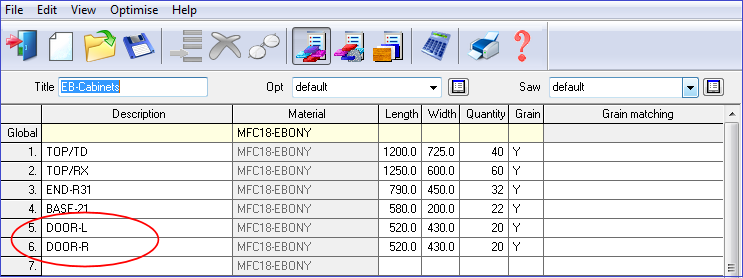

In the following example a pair of left and right cabinet doors need to be cut in a fixed arrangement so that the grain or finish matches closely across the two doors.

The fixed arrangement is defined with in the Pattern library. At the main screen:-

● Select: Libraries - Pattern library

Use the Pattern library to define a template pattern for the doors.

Although the template is defined in terms of the specific sizes it can be used for any range of part sizes that are required in this arrangement e.g. 2 doors each 1250 x 560. Use the Patten properties for the template to specify how the grain matching operates, for example, whether to cut the parts in the pattern or produce a jumbo or master pattern for the group of parts which is divided later.

Specify in the part list which parts are cut with this template.

Do this by setting up the Information box for grain matching (Main screen - Parameters - Information boxes). This is a one-off task and once set grain matching is available (if required) for all part lists.

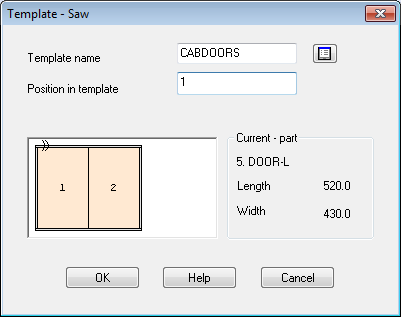

At the part list click on the Information box for each part that needs to use the template. The program pops up the Template information dialog

- Specify the position for the part in the template.

- Repeat this for the other part (door) and place it in the other position.

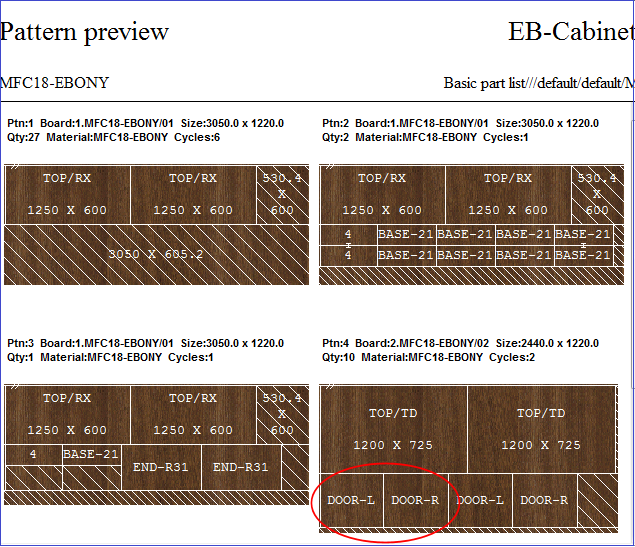

When the part list is optimised the parts assigned to templates are placed in cutting patterns in the fixed arrangement set by the template (in this example 1 x 2).

- Optimise the part list

(Make sure the 'Cutting list' and 'Board list' are up to date since the Cutting list is always adjusted to take account of grain grain matching).

In this example the doors are kept together in the correct arrangement and are cut with the main pattern. It is also possible to create them as a master part covering both doors which are divided later (see the Pattern library properties).

Master parts

It is also sometimes useful to use master parts for grain matching, for example, when the grain matched parts are cut on a separate saw or when the material has to be laminated after cutting on the main saw. In this case the main pattern contains a Master Part of the correct size for the parts in the template. The master part is cut in the pattern in the usual way and there is an extra pattern for later dividing the master part into the grain matched parts. (Master parts are also sometimes called: Parent parts)

Notes

Grained material only - grain match templates only apply if a material is grained. For example, if using variable material codes the template is only used (for making patterns) when the actual material is a grained material.

Laminate pieces for grain matched templates - are given the same name as the template piece prefixed with the letter ‘L’.

Pattern for master part - information box - this Information box provides the run number and pattern number for the pattern associated with the template part.