Details of input data for each run

At the Review runs screen:-

● Select: Summaries - Input

or

![]() Select the Toolbar option

Select the Toolbar option

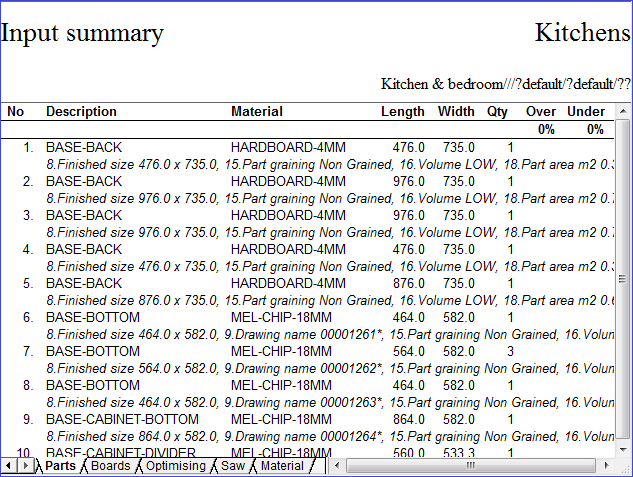

This report shows details of the parts required, boards selected, and parameter settings for each job.

The report is in several sections which show the following data: filenames and sizes, part list, board list (selected boards), optimising parameters, saw parameters and material parameters.

Use the Navigation buttons, Summaries menu or Stacked toolbar to browse the summaries. Many Review Runs options are also available on the Toolbar

adjust on-screen column and

row width

adjust on-screen column and

row width

![]() zoom display in / out

zoom display in / out

![]() print current report

print current report

![]() exit

exit

For full details of the on-screen options see help topic: Review runs screen

Notes

Files - This shows the files that are used for optimising. These are:-

Part list file (PNL)

Board list file (BRD)

Run file (PTN)

Optimising parameter file (PRM)

Saw parameter file (SPM)

Material parameter file (MPM)

Board parameter files (MPM)

The Part list file is the file storing the part list contents.

The Board list file is created automatically when you optimise or choose Select boards at the part list. It is the list of boards selected from the board library. It usually has the same name as the part list file.

The Run file is created when you optimise. This is the file that contains your results. It is based on a sequential run number that is generated for each optimisation. You do not usually need to know about this file because you always access the results using the part list name or batch name. The run number is always shown at the top of most screens and reports it is 5 digit number, for example: 00124. The program also creates extra files based on the run number to store other result information.

The optimising, saw parameter, and material parameter files are the files associated with the part list and the material parameters associated with the part list.

The Mode number indicates the measurement mode of the results (0 millimetres, 1 decimal inches, 2 fractional inches).

The important point about these files is that for valid results the date and time of the Run file must be equal to or later than the other two files.

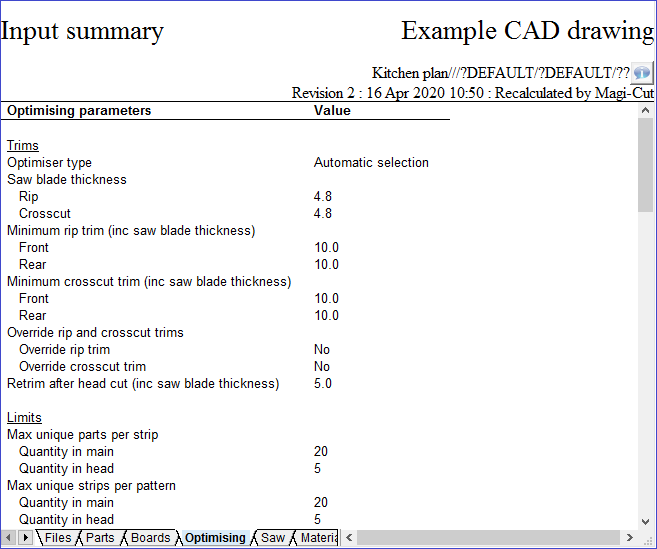

Optimising parameter details - This shows the settings of the optimising parameters that were in use when the part list was optimised. To repeat an optimisation you must make sure that the current settings of the optimising parameters match those in the input summary. Each line shows just the values of the optimising parameters in the same order that they appear in the optimising parameter list.

Saw parameter details - This shows the settings of the saw parameters that were in use when the part list was optimised. To repeat an optimisation you must make sure that the current settings of the parameters match those in the input summary. Each line shows just the values of the parameters in the same order that they appear in the saw parameter list.

Board limit - This is the value of the board limit for each board for the optimised part list.

Material parameter details - This shows the settings of the material parameters that were in use when the part list was optimised. To repeat an optimisation you must make sure that the current settings of the parameters match those in the input summary. each line shows just the values of the parameters in the same order that they appear in the parameter list.