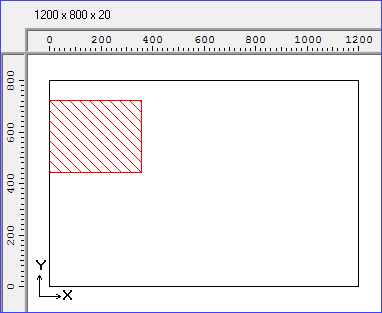

An enclosed area of a machining drawing which is completely routed out to a fixed depth

Drawing option for Machining

● Select: Function - Pocket

or

![]() Select

option from the Function Toolbar

Select

option from the Function Toolbar

A pocket has the shape of a rectangle with rounded corners. Pockets are used to accept fixtures that are recessed into the material such as door pulls. A pocket is defined by its centre point, length and width and the radius of the corners.

Move the cross hair cursor to the required location

First click - Start

Move to create area

Click to finish

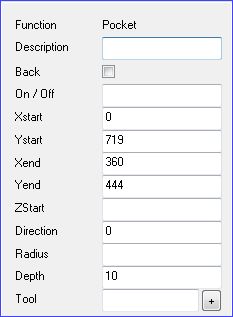

● Adjust the values with the Machining instructions pane at the left

Specify two opposite corners of the pocket using xStart/yStart and xEnd/yEnd boxes.

ZStart value - position in Z direction

Specify the direction the cut is taken in the Direction box. Use the direction to specify whether the generated instructions travel in an anti-clockwise (0) or a clock wise direction (1).

Use the Radius box to specify the radius of the router path.

The depth is specified in the Depth box. In the example Z stands for the part thickness.

Tool - use this box to enter the tool number and other information. Click on the [+] button to enter options via a dialog (this is only available for some types of machining centre).

Click to select the opposite corners of the pocket

WoodWop 4.0+ - For pockets the meaning of toolbox option F_ has changed from XY ratio to feed speed. Use: XY = for ratio (% added to path on each pass) instead of F_. Use FN=PK in the toolbox

WoodWop2.5 - Enter the command T=PK in to toolbox. You can also enter F_= and Z_= for the X/Y step and Z step if necessary.

The program automatically generates the correct macro command for the Homag MPR(X) file.