Use of equations and expression to define products and machining drawings

Formula can be used in the product library, machining library, drawing library (parametric drawings) and part library. They allow a more flexible, efficient and accurate use of library data. With formula several product variations or several different sets of machining instructions or different versions of the same drawing can be covered by a single library entry.

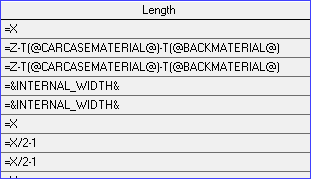

Almost any aspect of a product, drawing, or set of machining instructions can be associated with a formula.

Typical items that might be based on formula are those that vary between customers or jobs such as: materials, dimensions, quantities, fittings (hardware), the position and number of drilling or routing instructions, the proportions or contents of a drawing.

When and how formula are used depends on the type of products, production methods, etc - it is best to start with simple and obvious cases and gradually build up to more complex uses.

Variables - When using formula to describe aspects of a product or the machining of a part this means that some of the items in the formula are variable and depend on the specific values given for each customer or each job.

Enter the specific values for these variables whenever the product or part is required, that is, at the Quotes / Orders or Product requirements screen when the product and part requirements are entered.

Tables - Variables, formula and look-up items can be predefined and stored in tables. This is useful for complex items or where a variable or formula is used in several products or drawings etc.