Optimising parameter to set the number of head cuts

Quantity

Use the list box to enter the number of head cuts (1-5)

Use the list box to enter the number of head cuts (1-5)

Allow in rotated patterns

Allow in rotated patterns

Select this box to allow head cuts where the pattern is rotated. It is sometimes useful to not allow head-cuts in rotated patterns because the overall width of the head may be relatively narrow in a rotated pattern and also a head cut on a rotated board can be difficult to work with.

Allow in rotated parts in head

Allow in rotated parts in head

Select this allow parts to appear in both orientations in the head portion of a board.

Notes

- Can also be set as a material parameter at both board and material level

- If the number of head cuts is set to zero the other choices are not available.

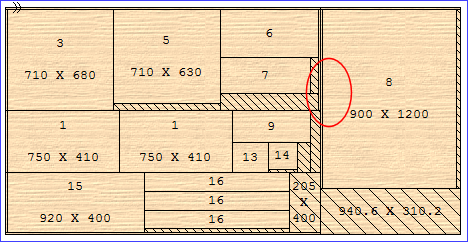

Patterns with Null heads

The optimisers may produce patterns with null (blank) heads if the extra cost of making the head cut (cutting time) is less than the value gained by producing the offcut. Null heads are not considered if there are parts that can be fitted into the space. This means that an offcut is never preferred to producing a required part. Any offcut considered must obey the minimum sizes for an offcut and is only taken if head cuts are allowed.

Null heads only - With some saws and ways of working it is useful to force the optimiser to produce patterns with null heads, where possible. To do this set the number of head cuts to 1 and set the number of strips in the head to 0. The program inserts null heads in all patterns where the falling piece is large enough to be a useful offcut.

|

|