Pattern editor option to create waste areas for a pattern.

There is sometimes a need for internal waste areas in a pattern. For example, a piece of waste between two parts in a strip, or a strip of waste between two strips of parts.

- Move to the required run

- Move to the required pattern

At the Pattern edit screen in Review runs:-

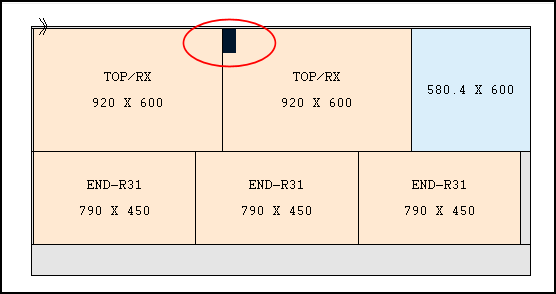

- Place the cursor to the right of where the waste part is inserted

Select the Toolbar option

or

● Select: File - Add waste part

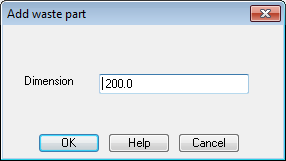

The program prompts for the dimension of the waste part (e.g. 200mm)

- Enter the dimension

The waste part always takes one dimension from the other parts cut by the same phase in the pattern (that is, the length of the block when inserted in a new strip, the width of the strip when inserted in a strip etc.). Normal pattern editor rules apply to waste parts (for example they must fit the free area).

● Select OK to confirm

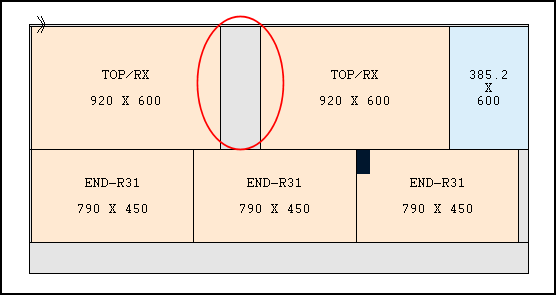

The waste part is added.

This only applies to patterns for the following saw models and for the CADmatic 3 and later controllers or sliding table saws.

21 - Single saw

22 - Angular

23 - Three saw system

24 - Angular with separate head saw

25 - Angular with turntable at rip saw

41 - Sliding table saw (the default for templates)

62 - SCM

Notes

- In addition to the CADmatic 3 and later versions, waste parts are also supported for import and export of Pattern Exchange formats (transfer modes 11 & 12).

- The dimension entered is the gap between adjacent parts / strips. It includes a saw blade thickness (the minimum needed to separate two pieces) and an extra piece of waste which is at least 0.1mm / 0.001" / 1/64". There is not necessarily a falling piece of waste (if it is less than or equal to the saw blade thickness).

- There is no restriction on the position of a waste part:- they may occur at the start or end of a strip and in these cases are not be absorbed into the trims / falling waste. In this regard they are treated as parts and require an extra cut.

- Once entered on a pattern, a waste part may be manipulated as a part (that is, copied, deleted, moved etc). They are identified as 'Waste part' in the current area section.

- Changing the saw blade thickness - If the saw blade thickness changes (e.g. when inserting a template pattern into a run) then the gap produced by a waste part will automatically remain the same as long as the new saw blade thickness is less than the gap originally entered. This also applies when a run's saw blade thickness is changed in optimising parameters.

- The maximum number of unique waste parts per pattern is 1500. A waste part is not identified as an offcut.

Waste parts and saw transfer - If a run contains waste parts and the saw model for that run does not support them an error is reported.

- Some saw controllers calculate the size of waste parts by assuming their dimension is net of the saw blade thickness which separates the waste part from the item to the left. In this case the waste part is entered with a size net of saw blade thickness but is only practical if waste size between parts is greater than 2 saw thicknesses. (Check with the distributor as typically the controller software can be updated to disallow this way of calculating the waste parts.