Send cutting patterns to a standard format file

The program can be set up to transfer data via the Pattern Exchange format.

Full details of the Pattern exchange format and it's use are in the 'Interface Guide'

Saw |

Transfer mode |

ASCII/Unicode (PTX) |

11 |

Access database format (MDB) |

12 |

At the main screen:-

● Select: Machine Interface

● Select the transfer option required

● Select: Transfer to saw

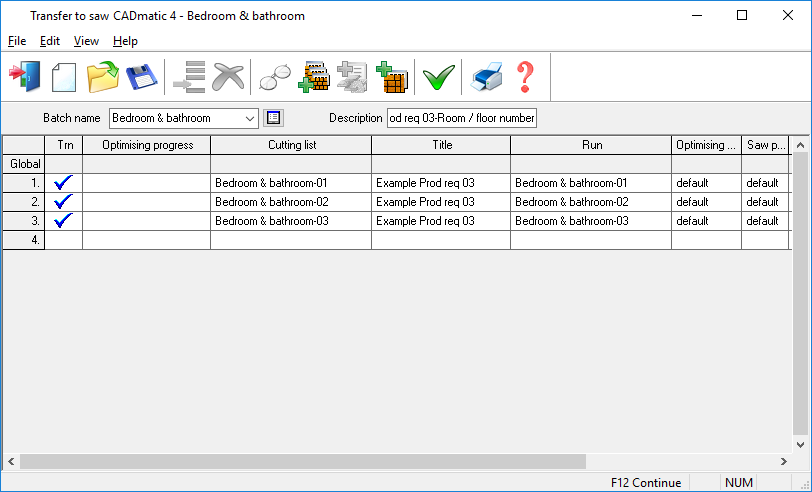

The program displays the batch screen showing the runs to be transferred

Select the 'continue' marker

Select the 'continue' marker

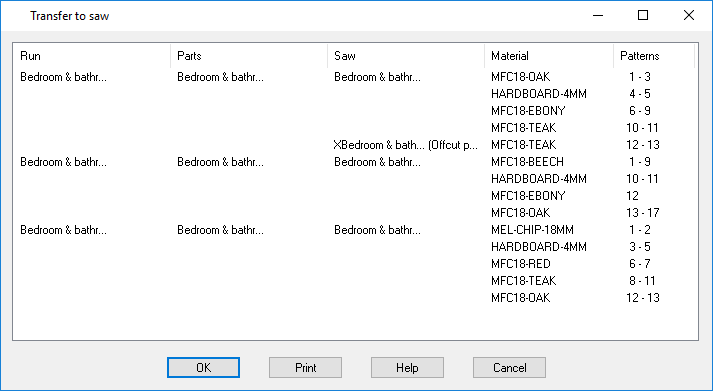

The program shows the specific details for each transfer and goes through the options required. This can vary for different types of saw controller.

● Select OK to confirm transfer

The information shown:-

Run number

Part list name

Name of file transferred to saw

Material code

Range of pattern numbers covered by file

The program creates a PTX or MDB file in the path set

Prompt before export - If the option to prompt is set the program prompts before export begins

Full details of the Pattern exchange format and it's use are in the 'Interface Guide'

Notes

- When using template patterns of type 'Create master part - divide at saw' the program cuts the master part from a board and appends a second pattern to further divide the master part. The second pattern needs no board itself, so only one board appears on the board summary.

- When the run is transferred to a saw an extra board record is normally appended to the export file (depending on transfer mode) to ensure the saw controller can process the patterns. The appended board record matches the dimensions of the master part.

Sometimes the presence of these appended board records can cause problems with external board stock management systems because the boards do not match stock records. The 'appended records' are marked with special text, [TEMPLATE], in the board information field of the BOARDS record. This allows external systems to identify this type of board.

Transfer to Pattern Exchange (ASCII/Unicode and MDB) 'Clone' part quantities

When the System parameter: 'Combine duplicate part quantities (retain duplicates with a quantity of zero)' is set this produces 'clone' parts. That is, the patters contains a single part type representing all the duplicates with a combined required quantity but when the information is transferred to the saw the quantities are re-allocated across the original part types.

The quantity of 'clone' parts produced is derived from the pre-aggregated quantity and any over/under setting. This quantity is stored in the QTY_PROD field of the PARTS_REQ records.

Overs / unders are allocated in proportion to original over / under values for clone part.

For example if 502 parts are produced in the cutting patterns the PTX file contains the following information.

Item PARTS_REQ PARTS_UDI

QTY_REQ QTY_OVER QTY_PROD Pre-Aggregated Qty

Part1 500 5 50 50

Part2 0 10 100 100

Part3 0 15 151 150

Part4 0 20 201 200

Destacking information

The destacking information is listed in the PARTS_DST record lines in pattern exchange data.

To output the PARTS_DST lines check the Saw transfer parameter: Create destacking data.