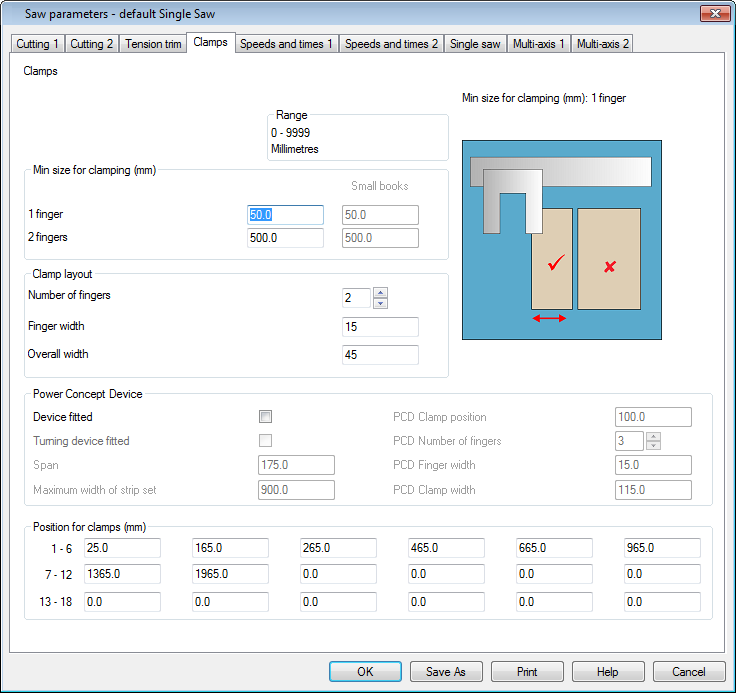

Set clamp layout, sizes and positions

Use these parameters to set the clamp layout and size and the position of individual clamps. Clamps determine how strips can be cross-cut and affect cutting times. Take care to set up the clamp information accurately.

For Angular saws the clamp information usually refers to the Cross cut saw.

Saw cutting times calculations - clamping rules

Calculation of clamp finger contact from adjacent clamps

The program uses the saw parameters 'min size for clamping' to determine whether a strip may be securely clamped by just part of a finger, one whole finger or two whole fingers (depending upon strip width).

In previous versions, the program considered only the finger contact with each clamp in turn. In this update the program considers the finger contact with all clamps.

This means that if a strip must be held by two whole fingers, those fingers may be on different clamps.

This modification means that a greater variety of strips may be crosscut together and will therefore reduce the cutting times for affected patterns.

Single fingered clamps

Modifications have been made to the cutting time calculations for saws with one-fingered clamps.

In previous versions, the program assumed that any strip could be clamped securely by a one fingered clamp if the whole of the finger was in contact with the strip.

Starting with this version, the normal clamping rules apply to single fingered clamps: if a strip is wide enough to require two fingers of contact, it must be held by two clamps.

This modification means that a smaller variety of strips may be crosscut together and will therefore increase the cutting times for affected patterns.

|

|