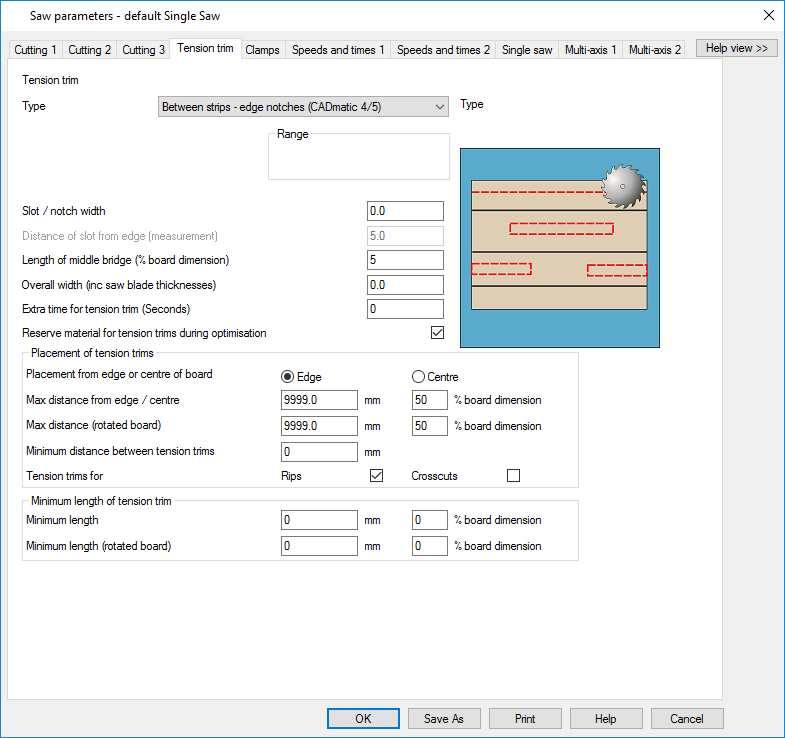

Settings for Tension trims (saw parameters)

A tension trim releases stress in a board as it is ripped or crosscut. This prevents distortion as the board is cut or the clamps are released. Typically tension trims occur for ripping (or for crosscuts where the strip width is large).

Tension trims can be configured for the following saw models:-

21 Single saw Homag/Holzma CADmatic 1/2/3/4/5 / Giben - Optilink / Selco - CRLINK

22 Angular Homag/Holzma CADmatic 1/2/3/4/5

23 Three-saw Homag/Holzma CADmatic 1/2/3/4/5

24 Angular Homag/Holzma CADmatic 1/2/3/4/5 (with offset head saw)

25 Angular Homag/Holzma CADmatic 1/2/3/4/5 (with turntable at rip saw)

91 Homag/Weeke Cutting Centre

There are several different methods of taking tension trims - use these parameters to set up tension trims.

- Select: Parameters - Saw parameters

- Select a parameter list

- Move to the Tension trims tab

First choose a value for the parameter: Type

The overall type of tension trim determines which parameters are required.

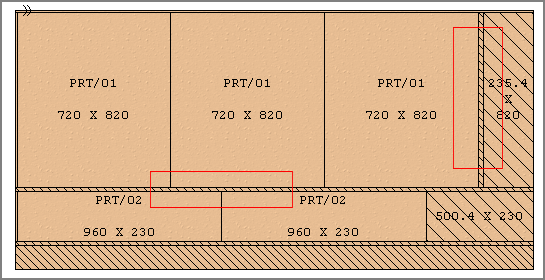

The example below shows a pattern with ripping and crosscut tension trims.

The tension trim parameters are explained in the help section: Tension trims