Saw parameter for cuts at the rear of the board

Use this to set a retrim for the 'last but one' rip cut and a value for the retrim - this allows for a tension trim that affects the last strip as it is released from the clamps.

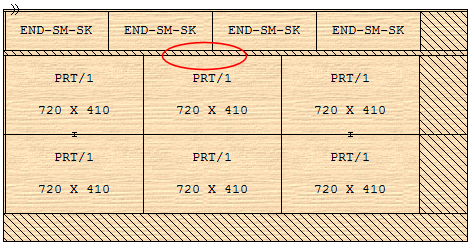

The last cut is usually taken with the material held by the hold-down cylinders whereas for preceding cuts the material is held in the saw clamps. When the clamps are opened for the last cut the strip may bend. This means that part will be slightly curved on its leading edge, but straight at the rear.

The re-trim on the last but one cut allows the clamps to be opened after the last but one cut, allowing the material to release its stress, and then the cut to be repeated so that both edges of the last strip are parallel.

Only one extra cut is usually needed and only if the last cut is in the rear half of the board.

Occasionally other tension relieving cuts are made in the board but these do not go fully through the material and are in the same place as the normal cut (which then completes the cut).

This is a material dependent parameter.

Specify the size of the trim (the amount of material to be removed). This can vary with the type, quality, and thickness of the material. Set a value of 0.0 if no retrim is required.

Notes

- Tension trim applies only to ripping main (not in head portions of a board). Only 1 tension trim and it is taken immediately before the rip for the final strip. The width of the last strip must be less than half the board width

- CADmatic .saw file - The tension trim is recorded in the MAT2 record and the PTN3/PTNR records or the SAW file. e.g. 1,1,1/B/2,3/4,4/

|

|