Edit Operations summary

At the Review runs screen:-

● Move to the run required (Review runs)

● Select: Edit - Operations Editor

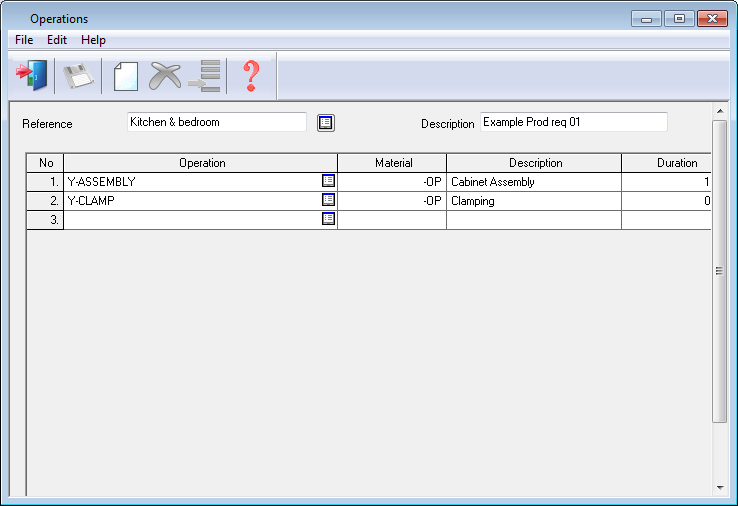

The screen displays the Operations screen and the cursor is positioned at the Reference box.. Enter a file reference or select an operations file with the List box.

Operations are any operation on the product, such as, assembly, cleaning, packing, etc. Product operations are not used in the optimisation and are stored in a separate file on disk. Use this list as a record of the operations required or as a check list to manage the jobs in production.

The time shown is the total time for all the products in the requirements list. The time is stored as seconds and shown as hours and minutes on the report.

The fields available for fittings are:-

Operation code

Operation - material

Operation - description

Operation - time

The material code must start with the minus symbol.

Edit the Operations list as necessary, change or delete existing items or add new entries.

Click

on the List buttons to view the Operations library and lists of Operation

files.

Click

on the List buttons to view the Operations library and lists of Operation

files.

Enter fittings - Fittings can be entered in the Part library in a similar way to parts.

![]() Insert line (also Return on last row)

Insert line (also Return on last row)

![]() Delete line

Delete line

![]() Print

Print

![]() New

New

![]() Save

Save

![]() Help

Help

![]() Exit

Exit

Custom operations - If working with custom products and use product variables to define the variable aspects of the products you may also need to do this with operations as well. For example, some operations may not be needed for some sizes of products or the time the operation takes may vary. Use variables for operations in the same way as for parts (see above for details on the use of variables).

Export - To export the operations list to a file select 'File - Export'. The filename is the same as the operations list name and has the extension EX4, for example, RXA15.EX4. The export file is in the: Path for export data