Rules for setting up master parts when optimising with grain matching

A 'master' part is used when optimising with grain matching. In this case the individual grain matched parts are not cut with the rest of the pattern but are combined into a larger 'master' part. The master part is cut but then divided into the grain matched parts at another saw or in a later process.

At optimising when the cutting list is generated the master part is created automatically based on the component parts. If Information boxes are set up the values are passed through to the master part where the information boxes are identical.

Part List

Description |

Material |

Length |

Width |

Qty |

... |

Bottom Edge |

Top Edge |

Left Edge |

Right Edge |

DOOR/01 |

EBONY-LAM-1MM |

750.0 |

520.0 |

1 |

|

|

EBONY-LAM-1MM

|

EBONY-LAM-1MM

|

|

DOOR/02 |

EBONY-LAM-1MM |

750.0 |

520.0 |

1 |

|

|

EBONY-LAM-1MM

|

|

EBONY-LAM-1MM

|

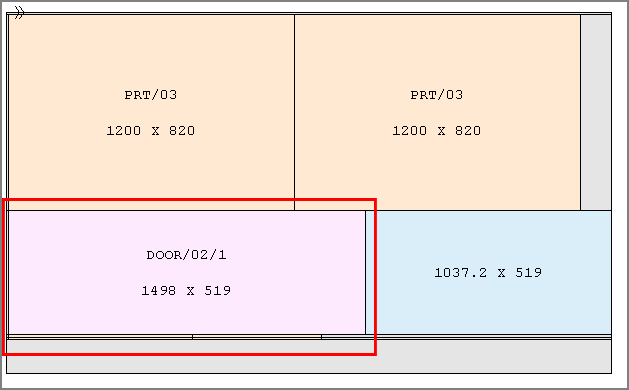

The Grain match master part information box values are taken from component parts

Cutting list

Description |

Material |

Length |

Width |

Qty |

... |

Bottom Edge |

Top Edge |

Left Edge |

Right Edge |

DOOR/01 |

EBONY-LAM-1MM |

750.0 |

520.0 |

1 |

|

|

EBONY-LAM-1MM

|

EBONY-LAM-1MM

|

|

DOOR/02

|

EBONY-LAM-1MM |

750.0 |

520.0 |

1 |

|

|

EBONY-LAM-1MM |

|

EBONY-LAM-1MM |

DOOR/02/01 |

EBONY-LAM-1MM |

1498.0 |

519.0 |

1 |

|

|

EBONY-LAM-1MM

|

|

|

In this case the only matching information box is: Top Edge and the values are copied to the master part.

Notes

- Front and back laminate values MUST match for all component parts and these are already copied to the template part. Any postformed (type 4) and bullnosed (type 5) edging of component parts is also copied to the template part.

- The pattern template in the Pattern library sets how the grain matching works for those grain matched parts.