Method of using Tooling instructions to transfer to different machining centres

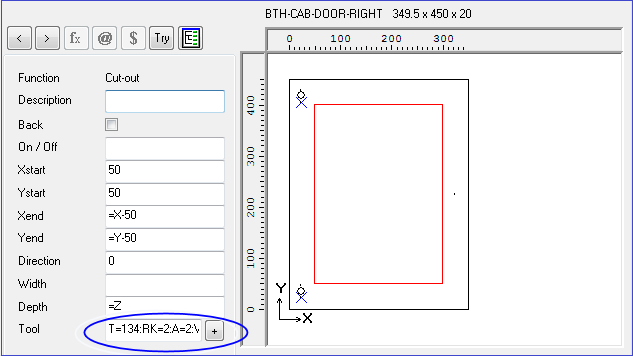

At the Machining library each machining instruction (rout, drill, pocket etc.) may also include a set of additional tooling instructions to control the machining centre operation. These are entered at the Tool box for each instruction at the Machining library.

For transfer to different machining centres it may be necessary to use a 'Tooling conversion' system because the instructions for one machining center may not be the same as another; for example:-

For Homag WoodWop V4+ the tool number may be expressed as T=32 but for another Machining centre it may be expressed as T=22 or TA=17.

In many cases the instructions are similar e.g. between different models in a range from the same manufacturer or when manufacturers use a similar standard.

To deal with this use the Machine transfer parameters to set up a transfer method to the each machining centre. These parameters can include a table which specifies how the various tooling instructions in the Machining library are to be converted (for example, from Homag WoodWop V4+ to a different machine)

Machine A Machine B

T=23 TA=17

EM=1 RM=3

MN=3 SP=2

Using a Generic tooling system

When creating a new set of parts/drawings it can be useful to start with a generic tooling system - this can make the drawing and instructions easier to follow and is more flexible. In this case create a set of 'generic' tooling instructions and set up a conversion table for each machining centre

Generic Machine A Machine B

ToolNo=23 T=23 TA=17

SetDown=1 EM=1 RM=3

GrooveMode=1 MN=1 SP=1

The generic code is used in the Machining library

This can also be a more convenient system where the instructions for machines are very different and it is not easy to do 1 to 1 replacements.

For example a generic instruction like DOWEL can be replaced by different multiple instruction streams.

Generic Machine A Machine B

DOWEL D=8:T=21 ZR=32[8]

Notes

- Tooling conversion is not available for runs that are optimised with the 'Project manager' option set.