Restrictions on the Tooling conversion system

The tooling conversion system appears as a grid at the left of the screen for Machining Centre transfer parameters.#

It is used to convert one set of tooling instructions to a different format when data is transferred to a machining centre. The following notes describe the rules for using the Tooling conversion system.

Limits

- Maximum lines in the replacement grid: 800

- Maximum characters for instruction: 50

- Maximum characters for replacement: 50

- Maximum characters for Tooling field: 255

Examples of allowed sequences

T1=1 T1=1 (copy instruction exactly)

T1=5 T1=12

T1=12 T1=14 (a loop net effect is T1=5 >> T1=14)

- Any string is allowed in the Replacement column

Separator characters for the Replacement column

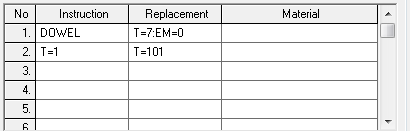

- The instruction does not have to contain and '=' symbol:-

Instruction Replacement

DOWEL D=8:T=21

ROUT12 T=101:RK=1:ABC

- Characters @ $ & : are NOT allowed

- each field is separated by a comma

- a field containing a comma is enclosed in quotes

- a field with quotes the quote is enclosed in quotes

MCH_TRANSINFO,0,Homag,8,c:\test\v12\Demo\Mch\,0,,,T=12,T=17,"T,=33","A=15:T""=14"

T=12 T=17

T,=33 A=15:T"=14

- Only one instruction can be entered in the Instruction column

- The tooling replacement is applied just before transfer

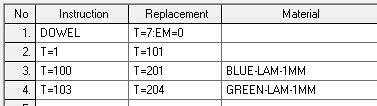

Material

The 'Material' column is used to specify that the Instruction/Replacement combination only applies for that specific material. If the material column is left blank this means that the Instruction/Replacement combination applies to all remaining materials.

(If there are specific material settings these must be entered first)

The above example indicates that whenever a machining instruction contains T=100 replace it with T=201 for BLUE-LAM-1MM

Notes

- Tool sequence parameters are applied after tool replacement rules.