How similar parts are defined and can be combined

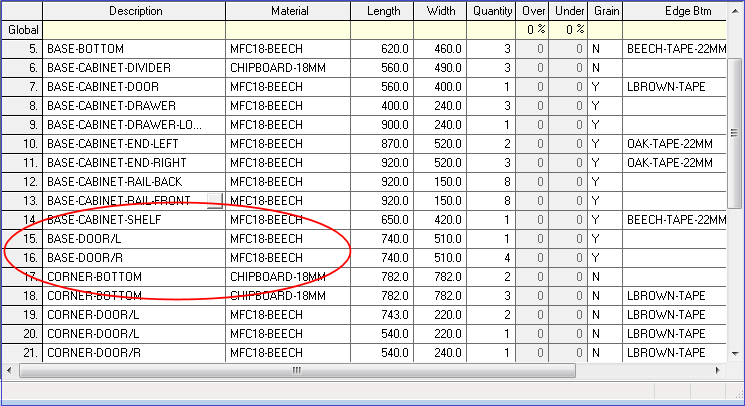

A duplicate part is a part which typically has the same material and dimensions as other parts but is labelled differently (a left and right hand panel or door is a common example).

Combine duplicate parts

It is often useful to be able to combine duplicate parts both as an administrative convenience and to improve stack heights when cutting. There are several cases where duplicate parts can be usefully combined.

Creating cutting lists from a requirements list or quote / order

Duplicates often arise when working with products. Use the Requirements parameters (at the Product requirements or Quotes / Orders screen) to set how the duplicates are defined and whether to combine parts or not.

At the Part list / Cutting list screen

Typically the cutting list is created automatically from the part list and duplicates can be combined at this point. There is also a manual option on the Part list screen to 'Combine duplicates'

- Use the Part list parameter: Fields for defining duplicate parts

- Check the settings in System parameters - these determine how the combine process works.

Creating patterns (optimising)

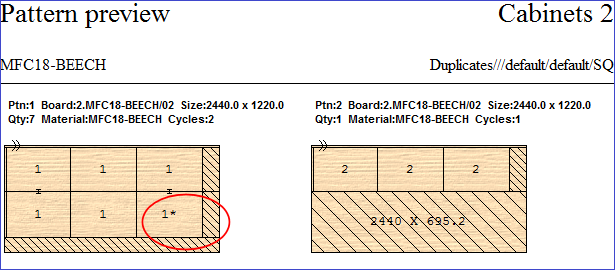

When optimising it can often be useful to combine duplicate parts as this may give a better stack height for cutting. Use the Optimising parameter: Fields for defining duplicate parts and the Optimising parameter: Duplicate parts to set how duplicates are defined and whether to combine them.

Edit duplicate parts

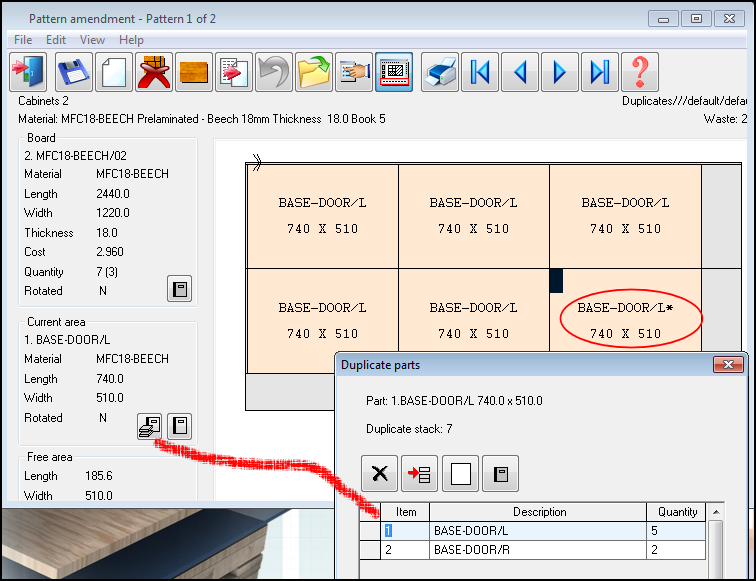

After optimising - patterns that contain duplicate parts can be viewed and duplicate part stacks edited or created as necessary.

This option is only available if the Optimising parameter: Duplicate parts - show in single pattern is set. At the pattern:-

- Select the required part

- Select the 'Duplicates' button (in the 'Current area' pane)

The program moves to the 'Duplicate parts' dialog where the duplicate stack can be edited or created.

Notes

- There is also a pre-defined Information box which can be added to the part list to hold a reference to duplicate parts - this is useful where the parts are combined but need to be identified for a later process.

- Pallet groups and duplicate parts. When the number of open parts/pallet groups is restricted (max open parts < the number of parts/pallet groups) only parts in the same pallet group can be aggregated (provided the relevant duplicate part criteria are met. However, parts in different pallet groups can be aggregated when there is no restriction on the number of open parts.

- Two optimiser types obey the Optimising parameter: Max open parts

Automatic selection

Medium quantity