Allocating the correct parameter lists to runs in a batch

It is quite common, especially where part lists are generated from a product explosion or imported, for the list to contain a mixture of parts, for example, some of which are processed on a saw and others at a machining centre.

To deal with this efficiently the part list is divided and the lists optimised separately.

Example

NS-P023 MED-DEN-FIBRE-18MM 750.0 x 450.0 20

PT/102 MED-DEN-FIBRE-18MM 820.0 x 590.0 15

PT-EN/1 MED-DEN-FIBRE-18MM 420.0 x 324.0 30

NS-P17 MED-DEN-FIBRE-18MM 605.0 x 520.0 24

NS-P412 MED-DEN-FIBRE-18MM 450.0 x 325.0 18

KR/T1 MED-DEN-FIBRE-18MM 720.0 x 350.0 25

In this example all parts for Nesting optimising start with the code NS- so the list has to be divided into two sub-lists.

Example-01

NS-P023 MED-DEN-FIBRE-18MM 750.0 x 450.0 20

NS-P17 MED-DEN-FIBRE-18MM 605.0 x 520.0 24

NS-P412 MED-DEN-FIBRE-18MM 450.0 x 325.0 18

Example-02

PT/102 MED-DEN-FIBRE-18MM 820.0 x 590.0 15

PT-EN/1 MED-DEN-FIBRE-18MM 420.0 x 324.0 30

KR/T1 MED-DEN-FIBRE-18MM 720.0 x 350.0 25

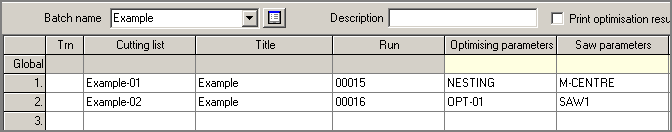

The batch that results contains two lists.

Cutting list Title Run Optimising Saw

parameters parameters

Example-01 Example 00009 ? ?

Example-02 Example 00010 ? ?

But each list may require different sets of optimising and saw parameters as they are processed by different machines. To achieve this use the following information boxes.

Optimising parameters

Saw parameters

When these are set an optimising and saw parameter list name is linked with each part.

Example Opt. Saw.

NS-P023 MED-DEN-FIBRE-18MM 750.0 x 450.0 20 NESTING M-CENTRE

PT/102 MED-DEN-FIBRE-18MM 820.0 x 590.0 15 OPT-01 SAW1

PT-EN/1 MED-DEN-FIBRE-18MM 420.0 x 324.0 30 OPT-01 SAW1

NS-P17 MED-DEN-FIBRE-18MM 605.0 x 520.0 24 NESTING M-CENTRE

NS-P412 MED-DEN-FIBRE-18MM 450.0 x 325.0 18 NESTING M-CENTRE

KR/T1 MED-DEN-FIBRE-18MM 720.0 x 350.0 25 OPT-01 SAW1

This information is passed to the divided part lists when they are created. The resulting batch is complete and ready to optimise.

In practice there are two issues to deal with:-

- The optimising and saw parameter names must be linked with each part

- The optimising and saw parameter information boxes must be set as the criteria for part list divide

Linking parts to optimising and saw parameter names

Whilst the information can be entered manually for each part it is more typical for the information to be generated automatically from a variable (via the product explosion) or from a cutting list rule (when the cutting list is created).

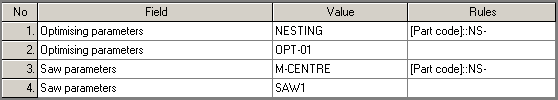

In the above example a cutting list rule (Libraries - Cutting list rules) was used to identify all parts containing 'NS-'

In general there are a wide variety of ways in which this data can be set up which depend on how the data is used and what rules are needed for linking optimising and saw parameter list names with parts.

Setting optimising and saw parameter information boxes as the criteria for divide

To do this move to the System parameters tab 'Divide part lists'. At the box 'Category for divide' all the fields and information boxes available are shown. For this example the boxes 'Optimising parameters' and 'Saw parameters' were checked. These are used as the criteria for 'Divide' at the Cutting list.

The Optimising and Saw parameter information boxes must be set up to appear in the above list. They are set up in the usual way via: Parameters - Information boxes. The boxes are in the 'Part' section of the list of information box types.

Notes

- The system parameter option to use the category name as the root for the divided name should not be used as the category name plus a root can exceed the allowed number of character.