Set how machining instructions are processed

The sequence in which machining operations are processed is controlled by the Tool sequence parameters. Use these to specify which machining instructions are processed first and which are grouped together ... At the main screen:-

● Select: Parameters - Tool sequence parameters

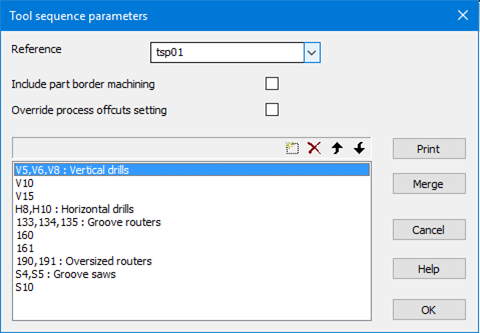

The program displays an empty Tool sequence parameter dialog:

● Enter a new set of parameters

or

Use the list option to select an existing set of parameters

Use the list option to select an existing set of parameters

Include part border machining - This allows for the tool sequencing to also apply to part borders (piece by piece, common edge or stay down)

Override process offcuts setting - This overrides the nesting parameter 'Process offcuts' so that offcuts may not be specifically machined first or last.

To create an entry enter the tool number(s) in the sequence required. Use the options on the tool bar at the top of the data entry box to add items or adjust the order.

![]() - add tool entry

- add tool entry

To alter the sequence use the mouse to select a line and then use the Navigation buttons to move the tool up or down the list.

![]() - move item up in priority

- move item up in priority

![]() - move item down in priority

- move item down in priority

To delete an item. Select the item with the cursor and select the delete option.

![]() - delete entry

- delete entry

Enter all tools where the sequence is to be controlled.

The values in the lines can be either tool numbers (e.g. 102, 128) or special instruction code (e.g. V10, H4). The special instruction codes are used where there is no tool number and the tool type is one of the following.

V - Vertical drilling

H - Horizontal drilling

S - Saw groove

Use the format Vxx where xx stands for the diameter or width value. For example 'V5' refers to any vertical drilling with a diameter of 5. For example:-

V5, V6, V9 : Vertical drills

103,105 : Groove routers

106

H8, H10 : Horizontal drills

The comma indicates that the items have the same priority and are used on the same line. The colon indicates a comment. Any commas entered in the comment section are not saved.

Reference

The box at the top of the screen shows the name of the current list. If a new list is created enter the name in this box before selecting 'OK' to save the details.

The options at the right of the dialog are:-

Print - print current set of parameters

Merge - add another list into the current list

On selecting this option the program prompts with a list of any existing tool parameter files. Select the list required.

Cancel - abandon changes and exit

Help - information on this dialog

Ok - confirm changes and exit

Notes

- The priority is from top to bottom of the list. Top is priority 1

- Any instructions not listed in the parameter file are processed after the file contents and part border routing

- A tool number can appear only once in the list

- Tool sequencing is not applied to the part borders; only machining/routing within a part.

- The parameter files are stored in the directory set by the System parameter: Path for data. The file extension is .tpm