How to set up the program to send data to CPOUT ASCII format with duplicate parts

The CPOUT ASCII format (used by some saws) has restrictions on the layout of the part list when there are duplicate parts. The duplicate parts must be sorted so that each set of duplicates forms a single block of data.

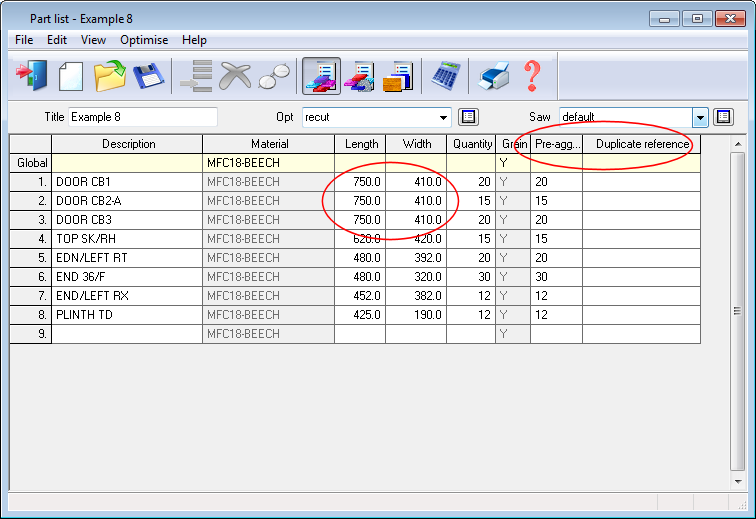

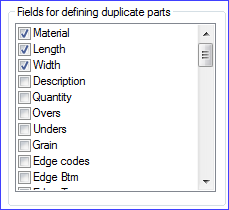

The list is sorted by Material, length, width in this example so the duplicates form a single block (the sort must match how duplicates are defined via the System parameter: Field for defining duplicate parts)

The following information boxes must be set up for the part list (Main screen - Parameters - Information boxes)

Pre-aggregated quantity

Duplicate reference

These are needed so the program can keep track of the information on the duplicate parts during optimisation and the correct data can be sent to the CPOUT file.

The system parameter: Create cutting list options must be set to the choice:-

Combine duplicate part quantities (retain duplicates with a quantity of zero)

This determines how the cutting list is created prior to optimising.

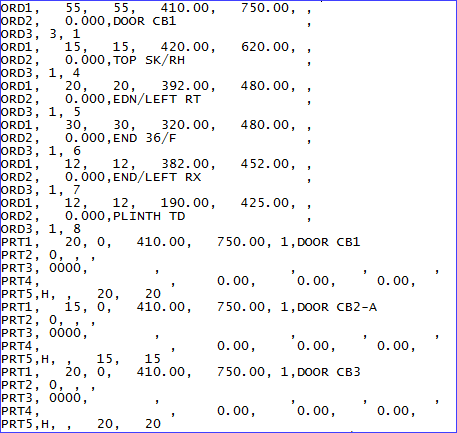

The duplicates are set up so the full quantity is assigned to the first duplicate in the set and the other quantities are set to a quantity of zero. This is a similar arrangement to the final CPOUT file.

● Optimise (in the usual way)

● Transfer data to saw (using the CPOUT (ASCII) transfer option)

In the CPOUT file is a single set of cut size records (ORD1, ORD2, ORD3) for each duplicate set and a multiple set of part records (PRT1, PRT2, PRT3, PRT4, PRT5) one set for each duplicate part.

Notes

- The ASCII CPOUT format supports single materials only. When transferring data containing multiple materials the data is divided into multiple CPOUT files automatically