Details on how combiTec recuts are taken

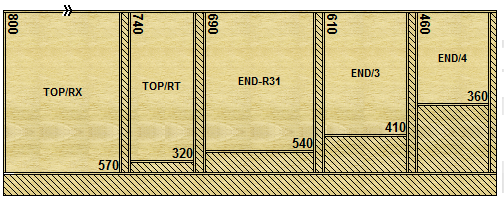

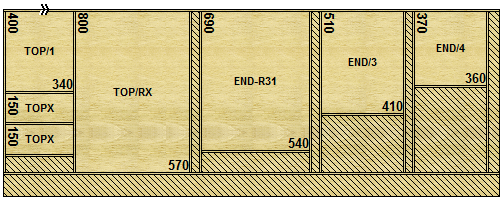

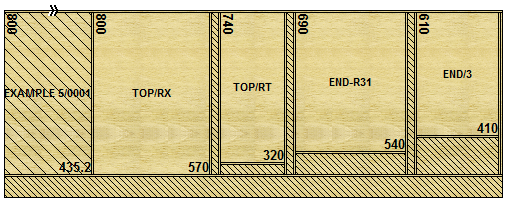

- Single (combiTec) recuts are sorted to the right (front) of each strip with the narrowest recut at the front

Where there is not enough space for the extra waste gap the combiTec cuts are not made and the single recut is taken after ripping and crosscutting.

- Parts which match the width of the strip are sorted to the left of the combiTec recuts and to the right of any multiple recuts

Multiple recuts (equal, unequal or unlimited) are sorted to the left (rear) of each strip. Multiple recuts are only allowed with manual outfeed.

- Offcuts can only be at the rear (left) of a strip containing combiTec recuts. Set the optimising parameter: 'Offcuts at end of cutting phase' to create offcuts at the end of a strip.

- A waste cut is inserted between a multiple recut block which is to the left of a combiTec recut.

- A waste cut is inserted between an offcut at the rear of a strip and any combiTec recuts to it's right..

Waste gaps - where the limits can be ignored

Waste gaps are inserted in order to allow combiTec cutting - if there is not enough space for the relevant waste gaps then a combiTec style cut is NOT taken as the cut would damage the adjacent parts. Also the parameters below relating to waste gaps must be obeyed.

Minimum part length (cutting direction at rip saw)

Maximum part length (cutting direction at rip saw)

In addition the difference in width between the parts connected by the gap must be greater than the parameter value:-

Minimum difference in width of adjacent recut parts.

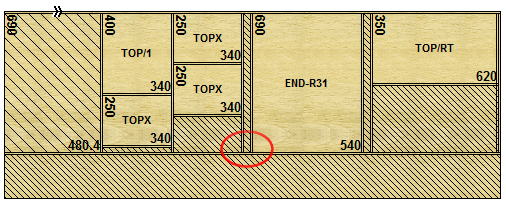

However, where the part to the left of the last inserted recut is also a recut but does NOT obey the value of the parameter: Minimum difference in width of adjacent recut parts. A waste gap CAN be inserted provided the width of the waste below the part does obey the value.

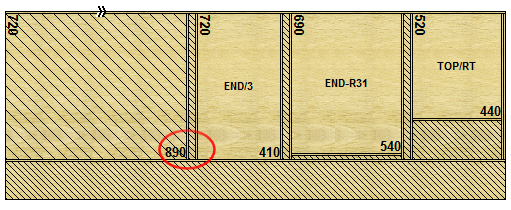

In the pattern below (without this rule) the waste gap between parts C and D could not be inserted because the difference in width of the parts is less than the allowed minimum. However, this rule allows a waste gap to be inserted in this case.

Notes

- It is assumed all boards of the same material have the same maximum book height. The maximum book height is the height in millimetres of a full book. e.g. maximum stack height = 200mm, material thickness = 12mm, maximum book height = 192mm

- In the pattern drawings 'waste parts' are inserted to represent the gaps between recut parts.

For combiTec see: combiTec |

|

|