Settings for Tension trims (saw parameters)

Saw parameter to limit the number of tension trims inserted between narrow strips (rip tension trims) or between short parts (crosscut tension trims).

Enter a measurement (e.g 300 mm).

The default for this parameter is zero (which means that it does not apply).

Parameter range: 0 – 9999 mm / 0 – 999 inches.

When calculating the requirement for tension trims, the program inserts a tension trim after every strip (rip tension trims) or after every part (crosscut tension trims) as long as the other tension trim parameters are satisfied.

Where the strips are narrow, this can lead to too many tension trims being inserted.

If the Minimum distance between tension trims is set to a non-zero value, the program inserts a tension trim only when a cut is at least this distance from the last tension trim.

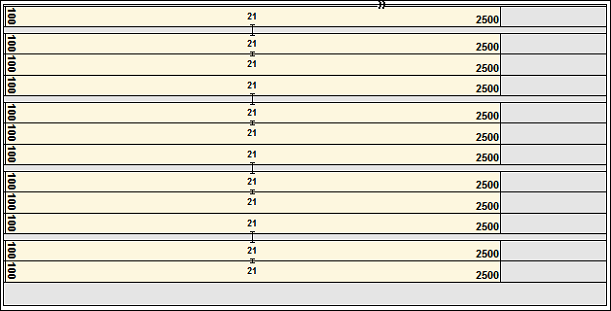

Example

In the following example, the strips are 100 mm wide and the Minimum distance between tension trims is set to 300 mm.

The program calculates that a tension trim is only required at every third strip.

Notes

- Can also be set as a material parameter at both board and material level

- CADmatic 3/4/5 only