Send results (cutting instructions) to a saw

For transfer to work correctly set Saw transfer parameters for each saw

Saw transfer is the process of sending the data for an optimised run to a saw (with a saw controller). The data is automatically created in the correct format for each saw type and controller. The saw type is set via the saw parameters and the saw controller via the saw transfer parameters. For example, 'transfer to a single saw with a CADmatic 4 controller'.

Once the part list is optimised, at the main screen:-

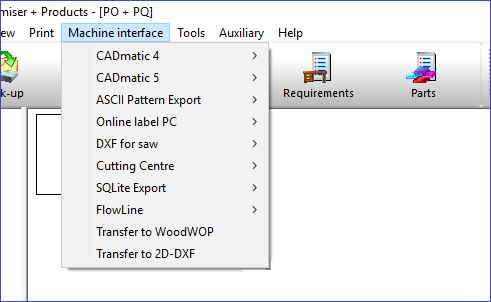

● Select: Machine Interface

Where more than one type of saw transfer is available (Saw transfer parameters) the program lists all the transfer types.

● Select a saw transfer type e.g. 'CADmatic 4' (must be already set up) and:-

● Select: Transfer to saw

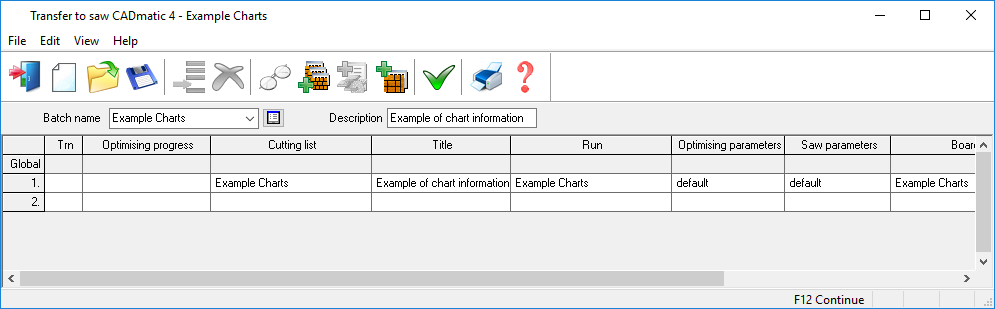

The program moves directly to batch screen for transfer (using the last transfer option chosen) and the current batch is shown. Make changes to the batch or select another batch with the usual options.

Select the 'continue' marker

Select the 'continue' marker

The program shows the specific details for each transfer and goes through the options required. This can vary for different types of saw controller.

To transfer a single run in a batch - select that run

Markers for transfer

A blue tick is shown if a run is already transferred to the saw. A red tick is shown in a run is transferred to a machining centre. Two ticks are shown where a run has be sent to a saw and a machining centre.

Notes

![]() The transfer option on the toolbar

automatically selects the first item in the list

The transfer option on the toolbar

automatically selects the first item in the list

- Where a run has already been transferred to a saw this is indicated by a light blue background. Use the Saw transfer parameters - options to set a warning level for controlling re-transfer of runs.

- Saw Transfer parameters - Each method (or mode) of transfer to the saw is set up via the Saw Transfer parameters. At the main menu select: Parameters - Saw Transfer Parameters. At this screen there is one row for each set of parameters; create a set of parameters for each saw or transfer method required, for example, to Transfer to a CADmatic Single saw and a Homag Single saw two rows are required. The right hand pane shows extra parameter settings for the current row - these are different for the various types of saw controller.

- There are several other saw interface options - buffered transfer, transfer with feedback from saw, send messages to saw etc. - only for some Saw transfer modes.

More than one run for a cutting list in the same batch - transfer to saw

It is sometimes useful to optimise the same cutting list against different sets of parameters so that waste and cutting times can be compared. To do this:-

- Set system parameter: Use sequential number for name of optimised run

- Add the same cutting list to a batch but with a different run number

The program prompts with a warning: -

Warning - multiple runs for one cutting list

- Select OK to continue

The transfer may still be cancelled at the next dialog.

- It is NOT possible to transfer a batch containing duplicate cutting lists to Pattern Exchange format (PTX) unless the system parameter: Create one file per run is selected. If this option is not set, the transfer is prevented.