Details of all offcuts produced for a run

An offcut is a usable piece of waste produced when cutting. At the Review runs screen:-

● Select: Summaries - Offcuts

or

![]() Select

the Toolbar option

Select

the Toolbar option

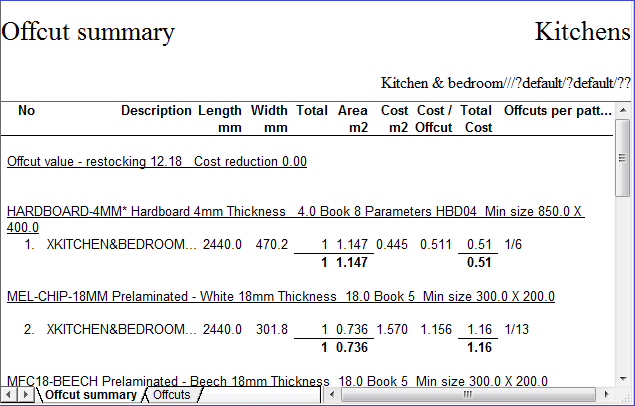

Shows the offcuts produced for a run; one line for each offcut. The offcuts are sorted in order of decreasing area. The top line shows the offcut value based on restocking cost and the cost reduction value. The values are on the rest of the summary are the restocking values.

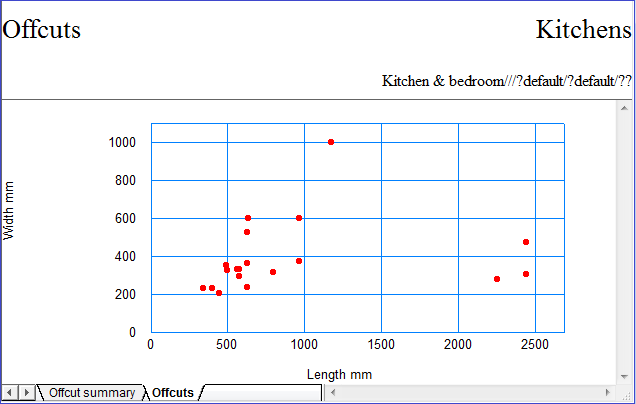

The tabs at the foot of the report can be used for custom graphs and charts, for example, a distribution of Offcut sizes.

As well as the default fields shown the report can be modified by removing or adding extra fields (see 'Settings - Report settings). A list of available fields for the report are shown.

Use the Navigation buttons, Summaries menu or Stacked toolbar to browse the summaries. Many Review Runs options are also available on the top Toolbar

adjust on-screen column and

row width

adjust on-screen column and

row width

![]() zoom display in / out

zoom display in / out

![]() print current report

print current report

![]() exit

exit

For full details of the on-screen options see help topic: Review runs screen

See: Offcuts

Notes

- Offcut value - This line shows the offcut value. This is the total value of the offcuts in terms of the restocking value and the cost reduction value.

- The restocking value is the same as the total at the foot of the report and is based on the original board cost less the value determined by the offcut allowance for restocking. This is the value at which offcuts are booked into the material library.

- The cost reduction value is based on the original board cost less the value determined by the offcut allowance for cost reduction. This is the cost used on the Management summary for reducing the cost of material for the run (because some material will be used as offcuts in future runs). The cost reduction and the restocking values are often different because there are extra handling and storage costs in using offcuts which can be taken into account in the cost reduction allowance.

- The offcut and stock boards are identified by the 'Type' field (blank for stock boards. 'X' for offcuts. There are also several different formats for the offcut board code that can be selected in System parameters (Rules 2 tab). The offcut code can also optionally include a prefix. e.g. 'X'. 'OFC-'...

- To get an offcut report set System parameter: Create data for

- The program uses the following rules to define an offcut. The offcut must obey the settings for minimum offcut length, width and areas For non grained material the longest edge is the length For grained material the edge running with the grain is the length Offcuts are sorted by material and are in decreasing order of area Maximum number of offcuts in a run is 200

- For a mixed material list the items are sorted by material. Each block of material is sub-totalled and the grand totals are shown at the bottom of the screen.

Offcut distribution

This field shows the offcuts per pattern. This is a list of the quantity of each offcut on the patterns which produce it.

No Description Length Width Total Area Cost Cost / Total Offcuts per pattern

mm mm m2 m2 Offcut Cost

1. 00101/0001 2440.0 470.2 2 2.295 0.445 0.511 1.02 1/2 1/3

In this example, offcut 00101/0001 appears once on pattern 2 and once on pattern 3.