Allow optimisers to run for a longer time

If the optimisers are run for an extended time this may enable the optimiser to improve yield and overall cost - but it may also take much longer to get a result.

These options are useful for jobs where an especially competitive answer is needed or where the material costs are high and even a small improvement in yield gives a significant cost benefit.

There are several options available.

Extended optimiser time

Extended recut optimisation

Extended headcut optimisation

Extended board combinations

Check

a box to include the option when optimising

Check

a box to include the option when optimising

Extended optimiser time

Enabling this option increases the number of combinations of parts and candidate patterns used during the optimisation. This option can significantly increase optimising time.

Extended recut optimisation

When this option is set the optimiser performs several additional optimisations using different recut settings.

Extended head cut optimisation

When this option is set the optimiser performs several additional optimisations using different quantities of head cuts and head cut positions.

Extended board combinations

Use this option when multiple board sizes are available to increase the number of combinations of boards optimised. This is especially useful when the maximum number of different boards parameter is set.

Example

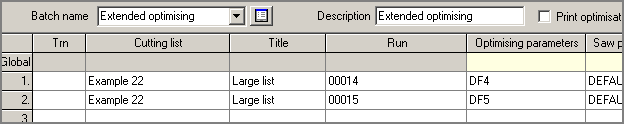

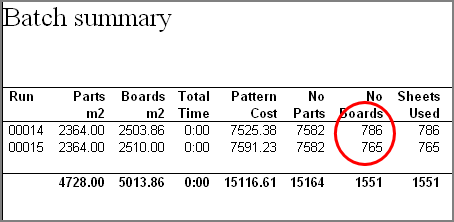

In the following example the same part list was run without and with extended optimising.

The result is shown below.

In run 15 with extended time for recuts and headcuts the number of boards used was reduced by 21 (2.67%) but the time taken to optimise the run was at least 10x longer.

|

|