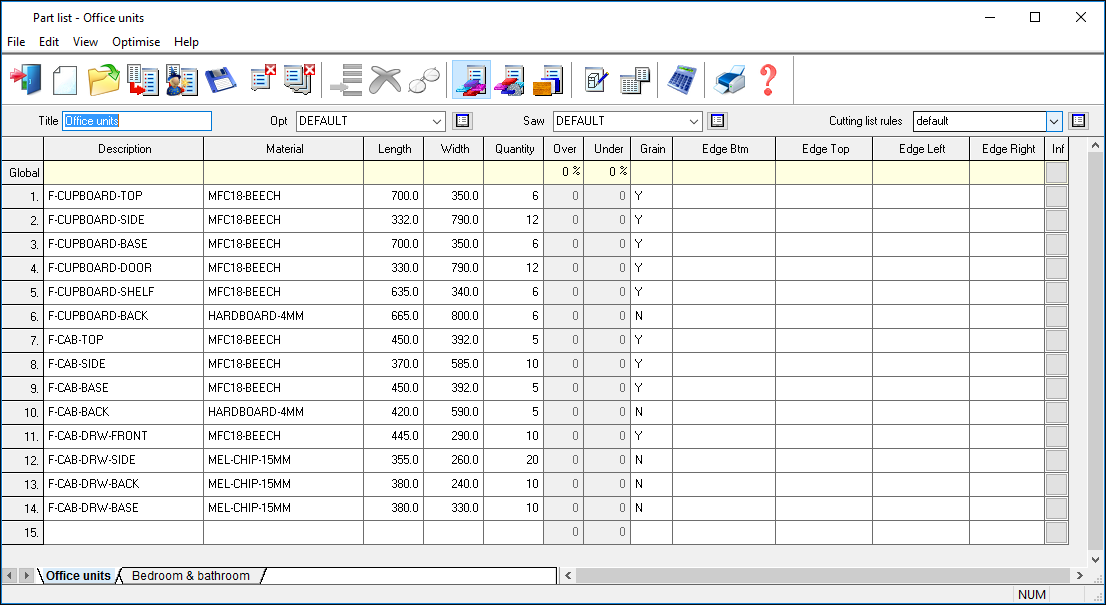

List of part sizes and quantities required

Part list data is entered at the Part list screen via a spreadsheet-like grid or imported from an external file. The basic data for a part list are the part cutting sizes, quantities and material. At the main screen:-

● Select: File - Part lists

or

● Select a list from part list section of the file tree

The part list screen is shown.

The Material code against each part must be one of the Materials in the Board Library. The program uses this code to identify the candidate boards for optimisation. From the part list the Program calculates a list of candidate boards (Board list) and a list of Cutting sizes (Cutting list) ready for optimisation. Usually the Part list is entered as the set of Finished sizes and the Cutting list takes account of any edging, core trims or other modifications to calculate the size for cutting on the Saw.

![]() Part list (sizes entered)

Part list (sizes entered)

![]() Cutting list (cut sizes - adjusted for edging ...)

Cutting list (cut sizes - adjusted for edging ...)

![]() Board list (available board sizes for this job)

Board list (available board sizes for this job)

![]() Optimise

(generate cutting patterns)

Optimise

(generate cutting patterns)

The Cutting list and Board list are optimised (from the Optimise button at the Part list screen) to produce a set of cutting patterns. When Optimising is complete the program moves to Review Runs to show the results.

![]() Once the results are checked they can be transferred to a saw for cutting.

Once the results are checked they can be transferred to a saw for cutting.

Import - Part list data can also be imported from external files; the import can be customised to cope with most file formats.

Multiple part lists

Up to 5 lists can be open at a time. The lists in use are shown on the tab at the foot of the screen.

Notes

- If a Part list is already optimised the program gives a warning message on opening the list:-

Patterns exist - changing list deletes patterns

This means that the Part list has already been Optimised and if the list is changed in any way the cutting patterns are deleted - this is done because any change to the data for example adding a part or changing a quantity invalidates the cutting patterns and they need to be re-calculated.

- If using Quotes/Order or Products the part lists are automatically calculated from a product requirement list.

Information boxes - The part list can be customised with extra fields using the Information box parameters. This can include user defined fields and predefined fields providing extra part list information. These fields have a wide range of uses, for example, placing data on printed labels, destacking, tracking numbers, extra edging information, storage instructions etc. Once the parameters are set up all Part lists include the extra fields.

- The Cutting list rules to be used with this part list can be set from the drop down list.