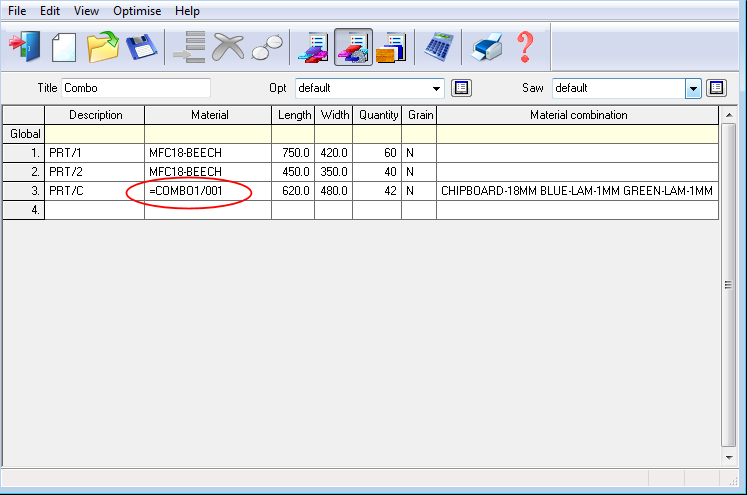

When creating a Cutting list (from the part list or when optimising) the program looks at each part in the part list and determines if it is pre-laminated or not. The program creates a material code for each pre-laminated part and overwrites the = sign with a composite material code, which is constructed as follows:-

=partlistname/nnn

For example:-

=EXAMPLEPRELM/001

The = at the start of the material code indicates that it is a composite material code.

Each composite material code implies a certain core, front laminate, and back laminate material (for example, RED MDF/18 WHITE. The program uses the laminate codes and core codes to work out the composition of each pre-laminated part. Parts with the same composition have the same material code in the cutting list, for example:-

Original part list

1. PART1 = 400 x 300 10 MDF/18 RED WHITE

2. PART2 = 500 x 300 10 MDF/18 RED WHITE

3. PART3 MDF/18 400 x 300 10

4. PART4 = 400 x 300 10 MDF/18 RED BLACK

Parts 1,2, and 4 are cut from pre-laminated material

Part 3 is cut from individual sheets of core and laminate and later pressed.

Cutting list

1. PART1 =TEST/1 400 x 300 10

2. PART2 =TEST/1 500 x 300 10

3. PART3 MDF/18 400 x 300 10

6. PART4 =TEST/2 400 x 300 10