How to set up and manage pre-laminated (composite, or combination) materials

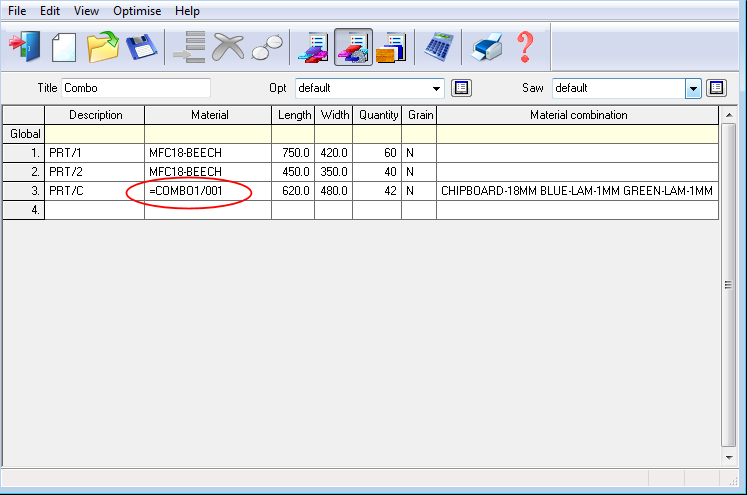

The materials required (core, front and back laminates) for a composite material are entered against each part in the part list.

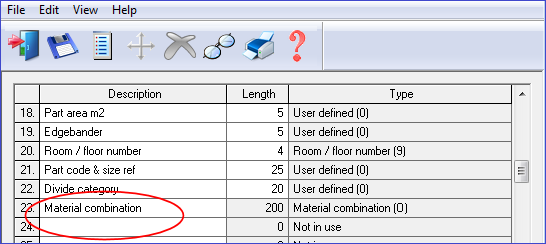

Before entering data make sure the pre-defined Information box: Material combination is set up (Main screen - Parameters - Information boxes)

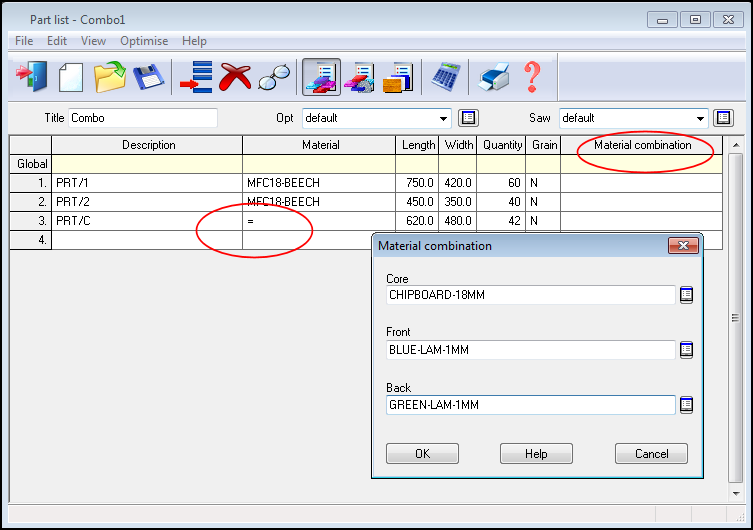

Enter parts in the part list in the usual way. For each part requiring a combination material enter a material code of: = or if using predefined combination boards enter the name of the material e.g. =REDWHT where the material will already be defined in your board library (use the See Also to view an overview of this process where the material description is used to define the boards used in combination rather than the information box)

In the above example part PRT/C uses combination material. At the Information box dialog for parts using pre-laminated materials enter the material codes.

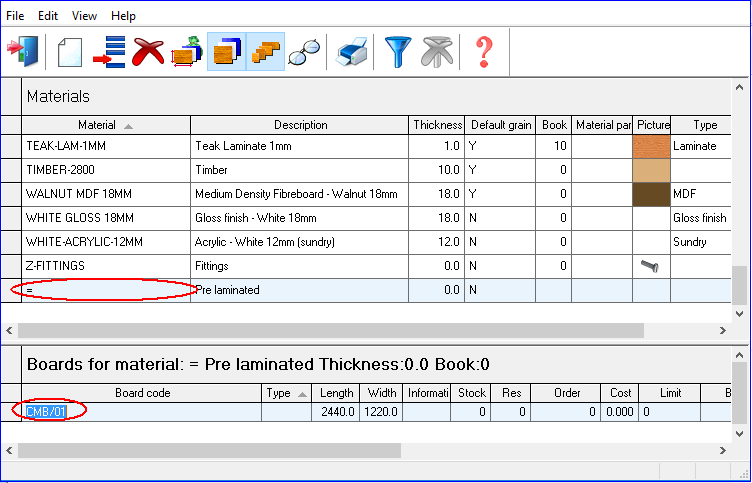

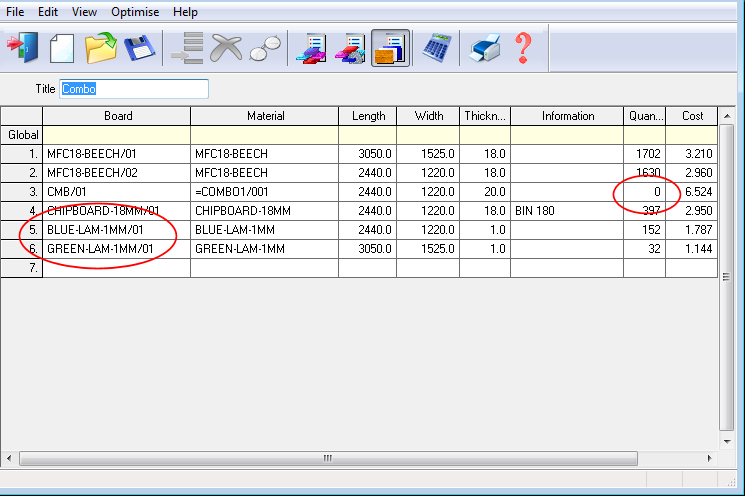

Make sure the Board library contains an entry (with Material code as =) and one or more board sizes for Pre-laminated material.

Pre-laminated boards do not exist as stock but the entry in the Board library allows preferred sizes and defaults to be set. The program attempts to match the stock sizes for core and laminates with the preferred pre-laminated board size. On optimising the program creates a cutting list and board list to deal with the combination materials.

Parts using Pre-laminated material have a new material code (part list name + number). This not a code in the Board library but a dummy code to represent the combination material.

Cutting list for combo materials

Each material code stands for a specific material combination, e.g. WHITE/MDF18/BLUE.

Board list for combo materials

The Board list is also adjusted to show the individual materials in each combination:-

CMB/01 is the entry for the Combination material and the following items are the core of stock materials it consists of. The size for the pre-laminated material is usually less than the laminates as these usually require a reasonable overlap for pressing. The preferred size of the pre-laminated material can be difficult to predict and it may need to be adjusted at the Board list depending on what material sizes are available.

The material description for composite boards is filled out with the material codes from the front laminate, core and back laminate (in that order) separated by ‘ + ‘ symbols. For example:

TEAK-LAM-1MM + MED-DEN-FIBRE-18MM + EBONY-LAM-1MM

If the combined material codes exceed the maximum for the material description field (50 characters) then the description is truncated to 50 chrs. For example:

EBONY-LAMINATE-1MM + MED-DEN-FIBRE-18MM + EBONY-LA

If the composite material is predefined (entered in the board library), the material description is taken from the board library record instead.

![]() Optimise

the part list / cutting list in the usual way

Optimise

the part list / cutting list in the usual way

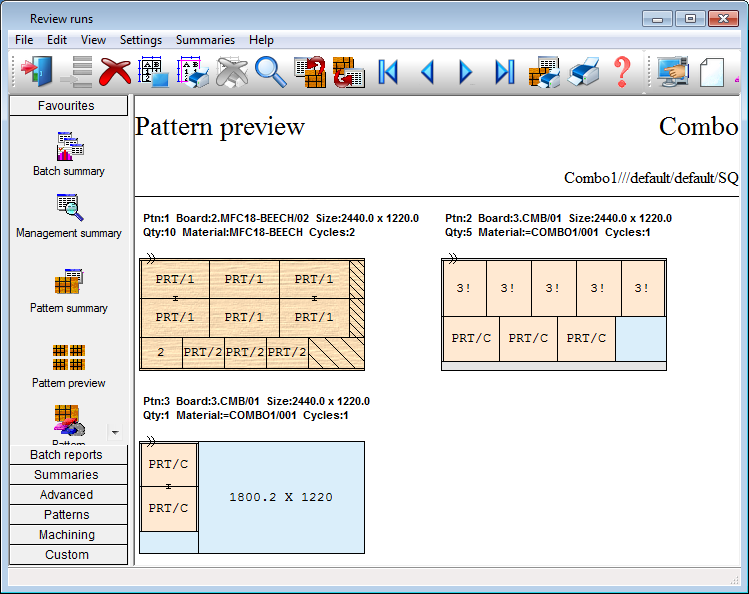

The result is a set of cutting patterns which include those for the pre-laminated material.

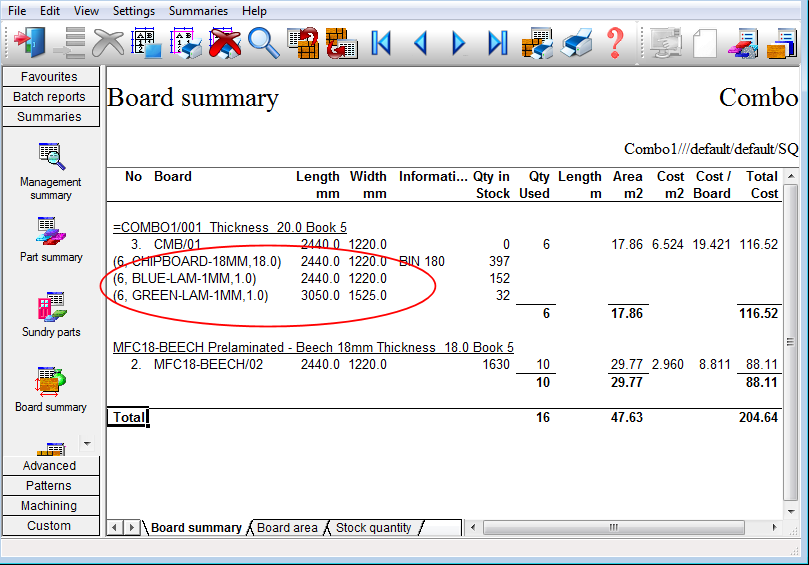

Summaries and patterns are adjusted to show the details of the Combination material.

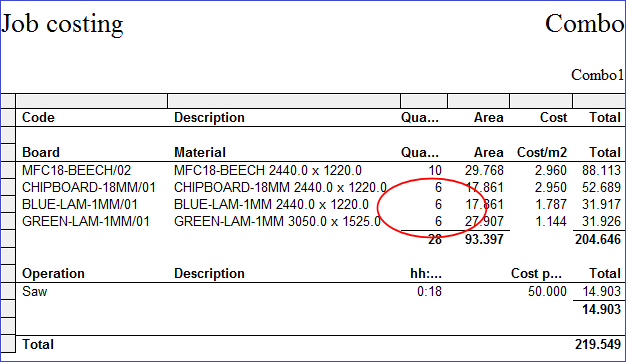

The Job costing summary shows the number of each individual board (forming the combination material) used.