How to manage over production of parts with the Part library

An 'Over part' is a part produced over and above the required quantity. These are either parts deliberately produced for stock or parts that arise from an allowed tolerance on the production quantities to minimise waste. These parts need to be stored and tracked so that when the same part is required for a future order the parts in stock can be made available before Optimisation so the cutting requirement can be reduced.

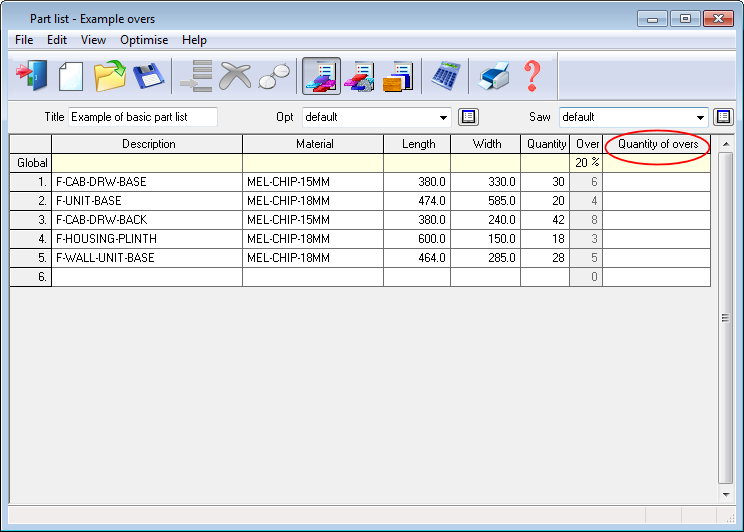

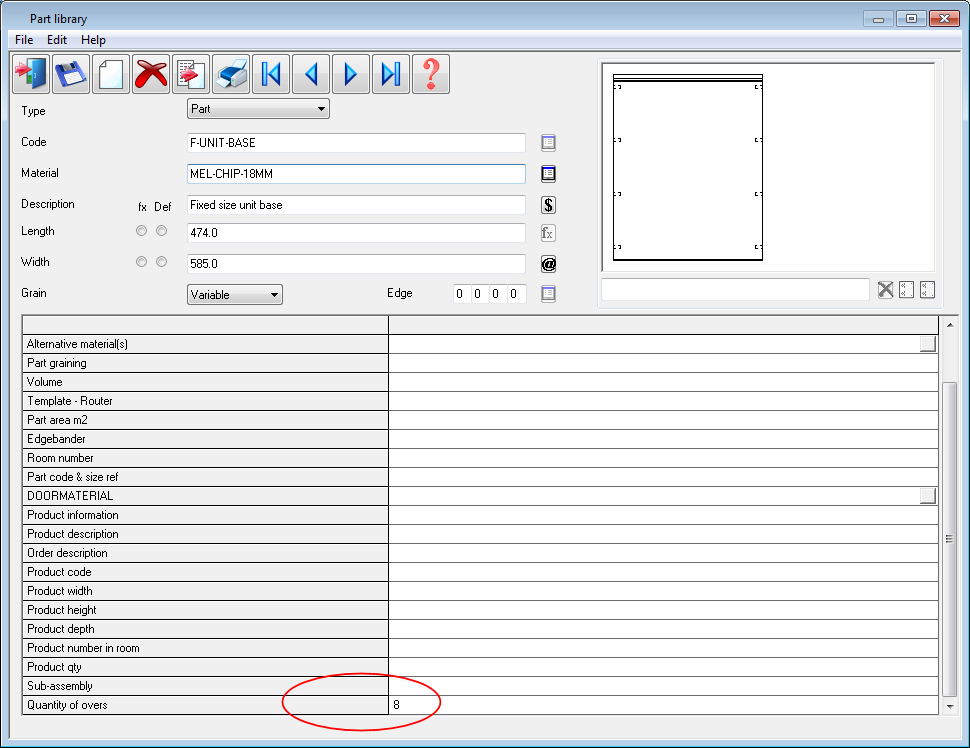

The quantity of over parts from a run is stored in an 'Information box' against each part in the Part library. An information box is a predefined custom field for parts and are set up via a list of parameters (Main screen - Parameters - Information boxes). The information box parameters add extra fields to the part list and part library.

Where a part list is optimised with overs allowed (as above) over production may result.

Any new overs created by the current run can be passed back to the Part library. At the Main menu:-

● Select: Stock - Update Overs from Runs

On choosing this option the program loads the current batch and displays the batch screen. The program prompts to confirm the update. After updating the program returns to the 'Adjust stock' menu. The stock update OVERWRITES the quantity of overs in the Part library - this is because the original quantity has been used/allocated to the current run and only new over production is available for the next run. The over production is stored in the 'Quantity of overs' field in the Part library.

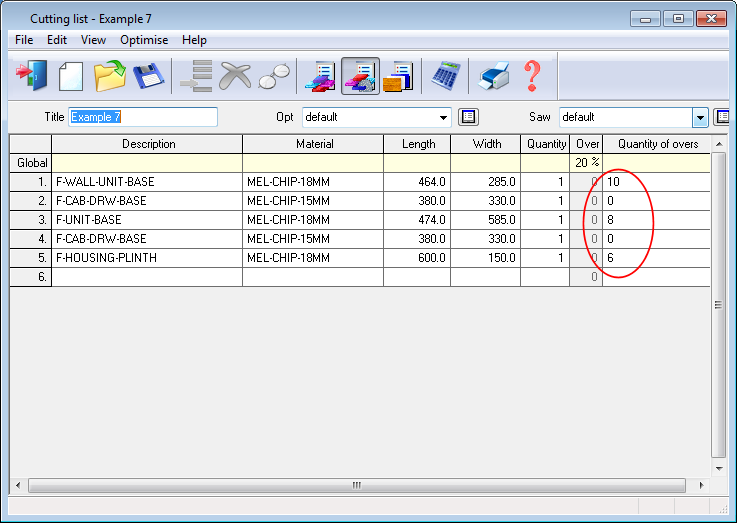

This overproduction is then available for future optimisations. As a new list is created any items that are added to the part list include any over quantities.

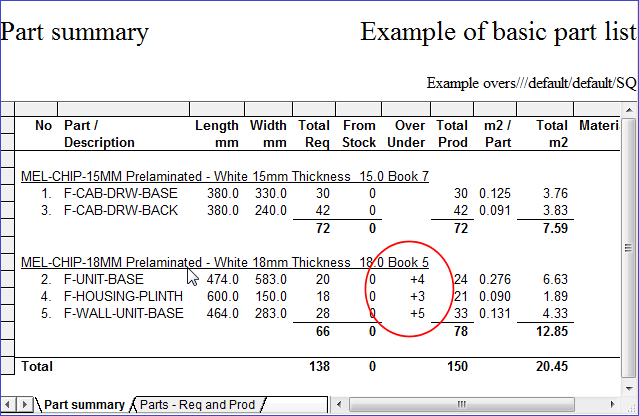

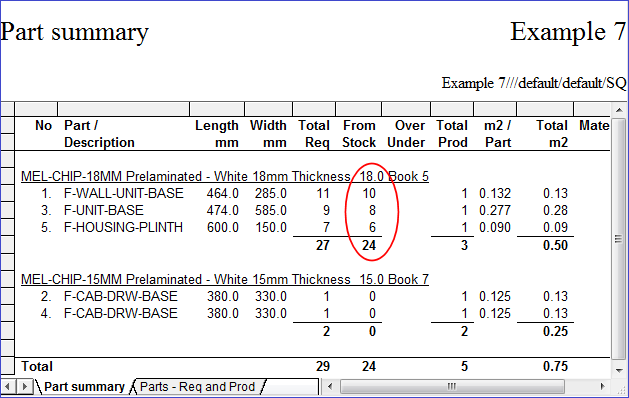

These parts are used with the optimisation. Any parts used appear in the 'From Stock' field at, for example, the part summary.

The report calculations are as follows:-

Tot req = quantity required + from stock

From stock = quantity from Part library

Any new overs created by the current run can be passed back to the Part library again ...

Manually change the overs in the part library

It is also possible to make manual changes to the overs stored, for example, if some are damaged. At the Main screen:-

● Select: Stock - Enter overs

On choosing this option the program displays a dialog to enter the number of overs for each part. Select part code and over quantity at the top of the screen then choose ADD to add the item to the list.

● Select OK to confirm the update

Notes

- The part library can also be edited directly to change the overs