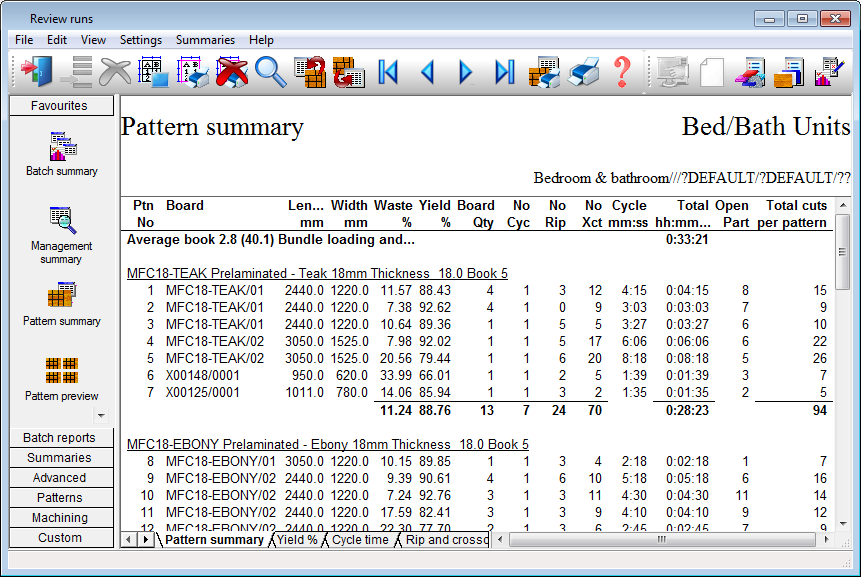

One line summary of each pattern created

At the Review runs screen:-

● Select: Summaries - Pattern summary

or

![]() Select

the Toolbar option

Select

the Toolbar option

The details of all the patterns used is listed grouped by material.

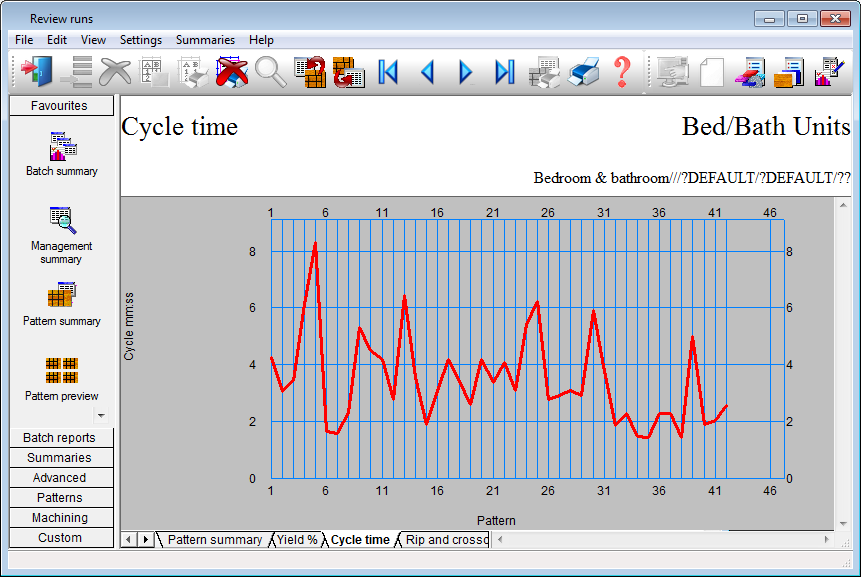

The tabs at the foot of the report can be used for custom graphs and charts, for example, for variation in cycle time.

Use the Navigation buttons, Summaries menu or Stacked toolbar to browse the summaries. Many Review Runs options are also available on the Toolbar

adjust on-screen column and

row width

adjust on-screen column and

row width

![]() zoom display in / out

zoom display in / out

![]() print current report

print current report

![]() exit

exit

The report content can be changed via the option 'Settings - Report settings'. There are a number of other fields and calculated data that can included in the report. For full details of the on-screen options see help topic: Review runs screen

Notes

- One line of information for each pattern. The report is sorted by material for a mixed material list. The grand totals are shown at the bottom of the screen. Note that cutting time information is only available if you have the relevant modules. The items on the reports are as follows.

- The top line of the body of the report shows the Average book height, number of boards. The value in brackets is the average book height in terms of measurement. These values are sometimes used as an approximate measure of saw performance,

At the right of this line is the bundle loading and pattern setup time. 'bundle'is a pack of boards ready for loading on the saw.

Cycles - The number of cycles is calculated by dividing the board quantity (or run quantity) for a pattern by the book height:-

Book height = 5

Item Board quantity Cycles

Pattern 1 4 1

Pattern 2 11 3

Pattern 3 12 3

Pattern 4 6 2

Waste - this is the waste as a percentage of the total area of board material used. The waste is shown for each pattern. Note that the average waste which is shown at the foot of each block of materials depends on the quantity of boards. For example, if you have a pattern with 5% waste with a board quantity of 3 and pattern with 10% waste with a board quantity of 1 the average waste is 6.5% not 7.5%.

Item Waste Board quantity

Pattern 1 5.00% 3

Pattern 2 10.00% 1

----- ----

6.5% 4

Cycle time - This the average time per cycle for cutting each pattern. The total at the bottom of the screen shows the overall average cycle time for the run.

Total cycle time - in hours (HR) and minutes (MN) for each pattern.

Number of open parts - This is the number of open parts. That is, parts where there are still items to cut to satisfy the requested part quantity.

Cutting time for Nested patterns

Cutting times for nested patterns are interpreted slightly differently and there are some extra fields that can be shown.

Cycle time - this is the time to load a board, rout (divide) all the parts, and take off each part this is comparable with the cycle time for cutting on a beam saw

The extra columns are: Dividing time and Machining time

Dividing time - total time take to rout out the board. Expressed in units of hours, minutes, seconds. For example with 5 boards with a routing time of 20 seconds; time = 5 x 20 = 100 seconds

Machining time - total time for the part machining. Expressed in units of hours, minutes, seconds. For example with 5 boards with part routine time of 30 seconds per board = 5 x 30 = 150 seconds

- The format symbols hh:mm:ss represent hours, minutes and seconds

- If any columns are not included in the report for Nested patterns they can be added via the Review runs option (Settings - Report Settings)