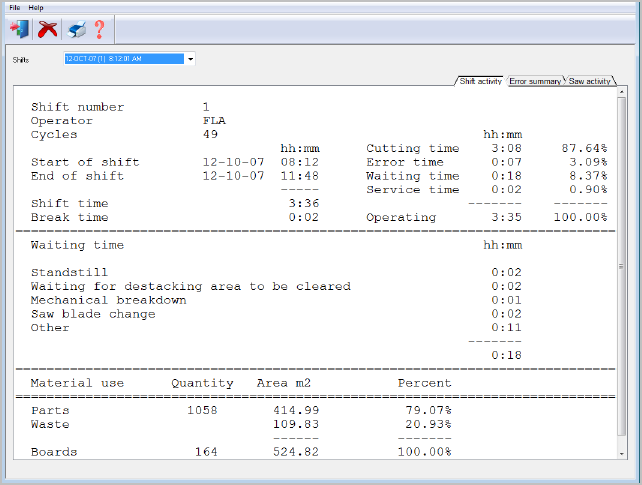

Summary of activity for a single shift

This reports shows the shift times, parts produced, boards used and machine downtime.

At the top right of the report are the shift date and number which identifies the shift.

The basic information on the shift is at the top of the report, showing the shift number, operator's initials and the number of saw cycles during the shift.

The 'time' information shows the start and end of the shift and the total elapsed shift time. The analysis of the time is split between the following categories:

Shift time - total duration of shift

Cutting time - time that the saw is cutting

Error time - down time recorded against saw errors

Service time - time for service operations (e.g.: change saw blade)

Waiting time - saw not in use:

Wait time = Op time - cutting - error - service

Break time - operator's break (for example: meals, rest)

Operating time - shift time less break time: Op time = shift - break

Below the 'time' information is the material usage during the shift. This shows the area of parts and board processed during the shift. The analysis categories are as follows:-

Number Code Meaning

1 START start of cycle

2 END end of cycle

3 ERROR start of error

4 CLEAR end of error

5 RESUME resume shift

6 BREAK break shift

7 SRV start service operation

8 END SV end service operation

Notes

- at the saw the operator needs to enter their initials or code at the start of each shift

- for some saw controllers Waiting time can be analysed into customised categories