Reports for shifts

These options provide analysis of the shifts recorded at the saw (feedback from the saw). These reports are only available for those saw controllers with feedback options. At the Main screen:-

● Select the menu option Machine Interface and the Saw required, for example, CADmatic 4

● Select: Analyse shifts

Click the box for a list of shifts

Click the box for a list of shifts

Each shift is identified by the starting date and the shift number. The name of the shift can include the start time (or for older formats the last activity of the shift is shown at the right). The shifts are listed in order of date / time.

● Select a shift

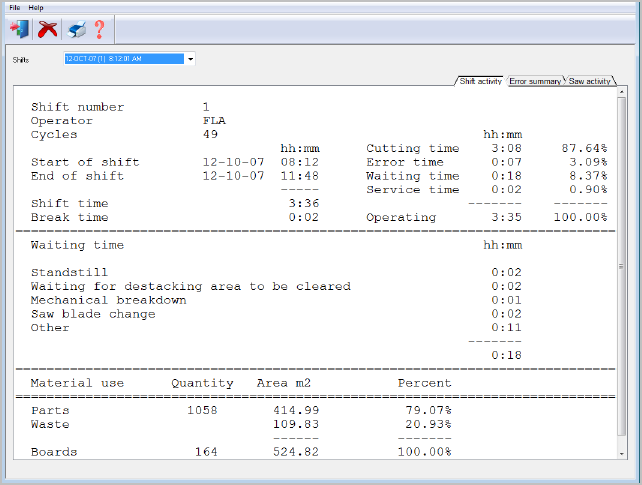

The Shift Activity report is shown:-

The Shift Activity shows a summary of the shift operations including the parts produced, boards used and a summary of any machine downtime.

● Click on the Tabs at the top right for more details.

Notes

- No data - if no shift data is available the program reports and error

- Feedback reports - overriding shift start/end time - where shift times are not filled out the time of the first and last activities are taken as the shift times. A * is added to the shift time to indicate this override.

- CADmatic 4 controller - some versions of this controller produce extended shift names where the name includes the shift start time. The list of shifts is sorted by date, shift number and shift start time (if available) irrespective of the time stamp of the shift activity file. Where a shift name includes the start time, the ‘last activity’ time of the shift is no longer shown.

- Feedback reports can show area or volume - to change this set the Review runs parameter: Use Volume for Boards and Offcuts. The software at the saw that produces the log files may also need to be changed. Do not change between these modes as the saw records either areas or volumes, not both.

- Shift number - where the Saw controller allows entry of non-numeric characters these are displayed as the shift number

- Pauses in a cycle - where waiting or errors occur within a cycle the saw controller records an extra cycle end and start in the log file to indicate that the saw is not cutting during this period. These extra cycles have a zero board quantity so that they can be easily identified. This time is taken account of in the analysis reports but these extra 'cycles' are not counted towards the number of cycles shown on reports.