Estimate of saw cutting times and process

For each pattern in a run the program can simulate the saw operation using the times and other values from the Saw parameters. The simulation result is a time-line showing the saw activities. This includes an estimate of the average cycle time. To see a simulation report for a pattern:-

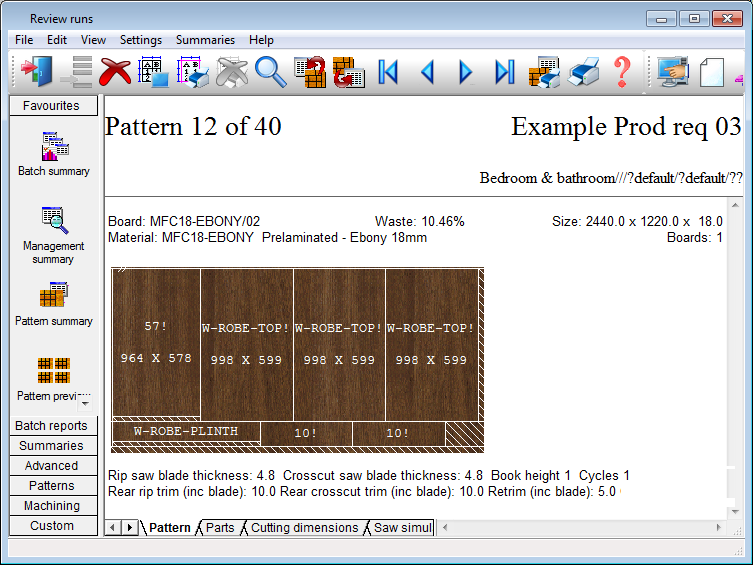

● Select an optimised run

● Move to a pattern

● Select the Simulation tab

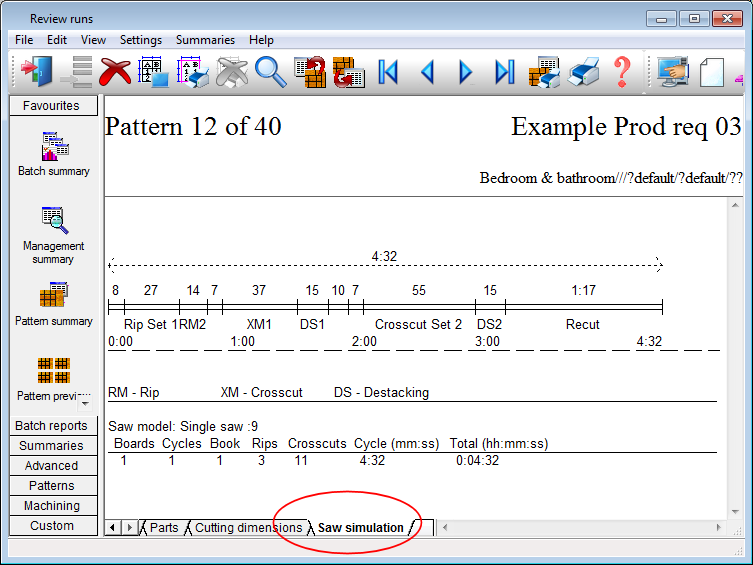

The above example is for a single saw.

Time-line moves from left to right and may spread over several lines.

Time-line is split into separate sections for each saw operation, for example, loading and feeding, Head cut, rip head etc.

Time for each section is shown above the line

Cumulative times are underneath the line

At the foot of each report is a description of the operations involved and a summary of the pattern

Examples of saw operations:-

PS - pre stacking time

FD - load and feed time

RM1 - time to rip main

TS - time to turn strip 1

DB1 - time to draw back first strip

XM1 - time to crosscut first strip

DS1 - time destack parts from first strip

The numbers refer to sets of strips and parts. XM1 for example is the first set of strips and XM2 the second.

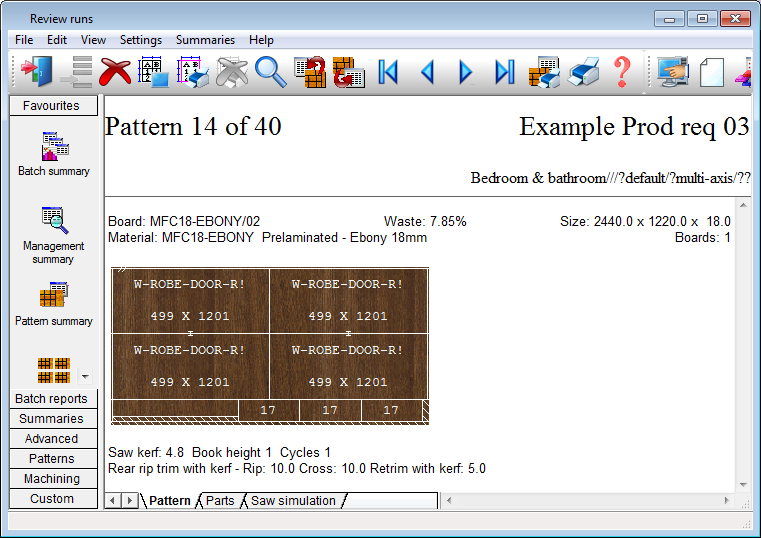

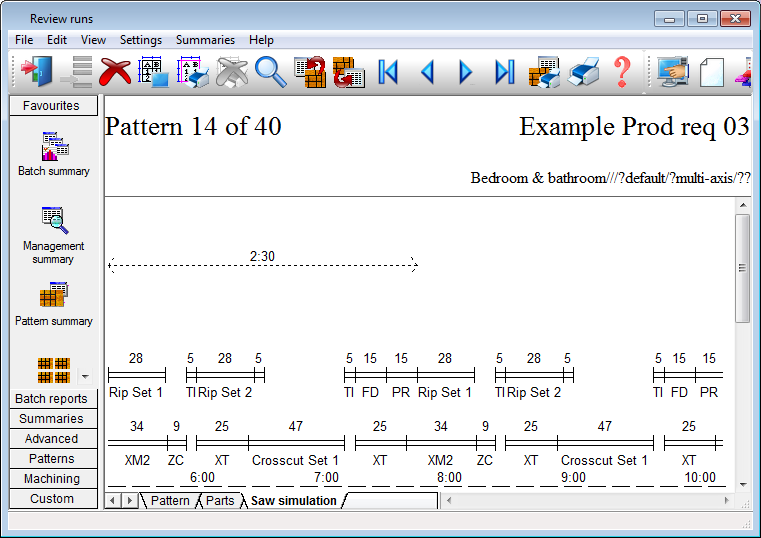

The simulation for an Angular is more complex as there is a Time-line for each Saw blade and operations can be simultaneous.

The simulation shows the simultaneous cutting for rip and cross cut.

For an angular saw the simulation (where possible) shows the saw in the midst of an average cycle because the initial and final cycles can be very different.