Send results (cutting instructions) to CADmatic saw types

There are several CADmatic transfer methods. These depend on the saw controller in use at the saw.

Saw |

Transfer mode |

CADmatic 1 |

3 |

CADmatic 2 / Micromatic |

4 |

CADmatic 2 with feedback |

5 |

CADmatic 3/4/5 |

6 |

At the main screen:-

● Select: Machine Interface

● Select the transfer option required

● Select: Transfer to saw

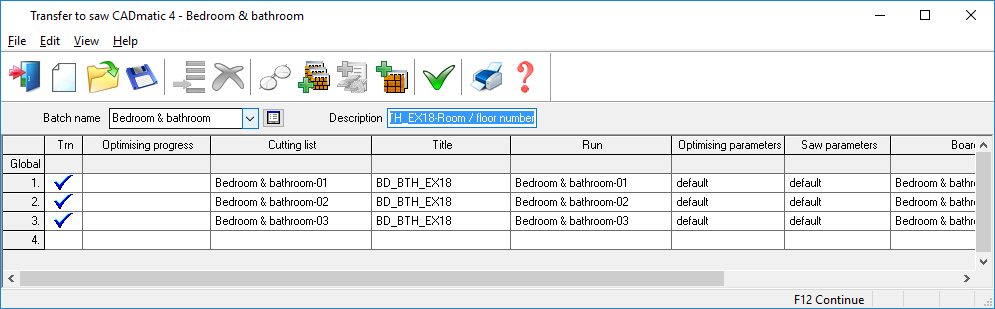

The program displays the batch screen showing the runs to be transferred

Select the 'continue' marker

Select the 'continue' marker

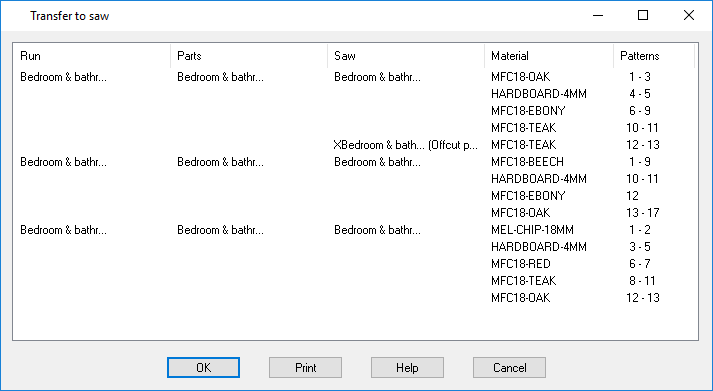

The program shows the specific details for each transfer and goes through the options required. This can vary for different types of saw controller.

● Select OK to confirm transfer

The information shown:-

Run number

Part list name

Name of file transferred to saw

Material code

Range of pattern numbers covered by file

CADmatic link - the CADmatic and the PC are linked over a Network

Label printing at the saw - For the CADmatic transferred data includes the information necessary for printing labels at the saw. For CaDmatic 1 and CADmatic 2 the Label design option in the Optimising program can be used to design labels and transfer the design to the saw. Other CADmatic types provide a label design option separately.

For the transfer to work correctly the Transfer mode must be set to the correct saw type via Saw Transfer Parameters

Notes

- Transfer to CADmatic 3/4/5 - Parts with no edging - When information boxes are used for edging codes the contents of these boxes are exported to the CADmatic 3/4/5 .saw file during saw transfer. If a part had no edging on one side, the exported edge code is set to blank.

- Transfer programs. Optionally a transfer program can be set for CADmatic 3/4/5 (Saw transfer parameters). This is program is run after the data files are created. In previous versions the Optimising program passed the path for the current directory to these transfer programs. This path is no longer required by these programs and is not passed to them.

Destacking information

Destacking information is listed in the DSTPNL2 record lines of the .SAW file.

To output the DSTPNL2 lines check the Saw transfer parameter: Create destacking data.

CADmatic 4/5

Board parameters and grain match template parameters that are specified at the board level are passed to the .SAW file in a pattern parameter line named. PTNP