Commit boards and update board quantities

When a run (optimisation) is cut at the saw update the stock system with the boards used. This process is called: Issue Stock. At the Main screen:-

● Select: Stock - Issue stock - runs

or

Select

the Toolbar option (Stock)

Select

the Toolbar option (Stock)

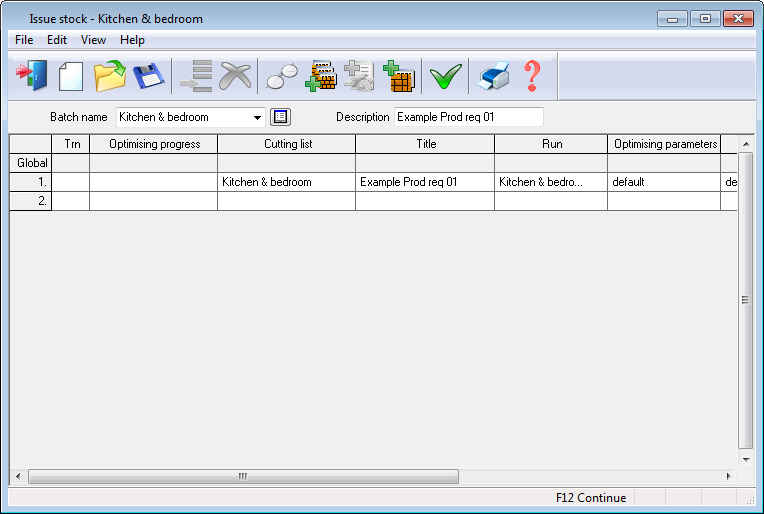

The program displays the batch screen showing the current (most recently selected) batch.

● Select or confirm the batch required

Select

continue

Select

continue

- Once a run has been used for a stock issue it cannot be manually changed or re-optimised

If there are any problems with the issues these are reported as errors at the end of the issue. The most common error is that a run (part list) in the batch has already been used for an update (it cannot be used twice).

Whilst issuing stock if the stock quantity of a part on that run fails below the minimum stock quantity then a warning message is displayed.

At the end of the issue the program returns to the main menu

Notes

Extra security for Stock issues - issue stock for runs locks the associated part lists on which the run is based - so there is no danger of issuing stock twice for the same list.

If a part list is accidentally locked it cannot be undone. In this case create a new list and use MERGE to rescue the part list data.

Updating the board library - The action of 'Issue stock - runs' also adds any offcuts produced by a run to the board library.

The offcuts are stored in a file: run-number.BRD for example, 00023.BRD.

Normally the offcut code is based upon the run number, which is different for each run, it is therefore unlikely that any offcuts with matching codes already exist in the library. However, if this does occur there are additional checks to make sure that the material length, width and thickness all match. If an offcut is found from the library where the code matches a code from the run but the other fields are not the program reports an error.

Board Library (before update) Offcut file

B1 CHIP15 2440 x 1220 10 X00006/1 CHIP15 600 x 400 1

B2 CHIP18 3000 x 2000 10 X00006/2 CHIP15 320 x 420 1

X00001/1 CHIP15 600 x 400 2 B2 CHIP15 3000 x 2000 20

X00001/4 CHIP15 320 x 420 1

Board library (after update)

B1 CHIP15 2440 x 1220 10

B2 CHIP18 3000 x 2000 30

X00001/1 CHIP15 600 x 400 3

X00001/4 CHIP15 320 x 420 2

X00006/1 CHIP15 600 x 400 1

X00006/4 CHIP15 320 x 420 1

A detailed check ensures that errors in the offcut file do not corrupt the board library. For example:-

Board Library (before update) Offcut file

B1 CHIP15 2440 x 1220 10 X00001/1 CHIP15 500 x 400 1

B2 CHIP18 3000 x 2000 10 X00006/2 CHIP15 320 x 420 1

X00001/1 CHIP15 600 x 400 2 B2 CHIP15 3000 x 1500 20

X00001/4 CHIP15 320 x 420 1

In this case the sizes for code X00001/1 do not match and an error is reported. Items with matching codes must also match in length, width, material and thickness.

- Where offcuts from a run are added to the Board library the offcut cost is added back as a cost per area and the Cost Method set to 0 for that offcut.

The following rules are also observed when the audit is maintained for offcuts.

- Issue stock no longer deletes offcuts from the board library when their stock quantity is used up.