Optimising parameters to set how recuts are taken

Typically recuts are taken at the saw (or on a separate saw) as the final phase of cutting (after ripping and cross cutting) but there are also other devices and methods for taking recuts.

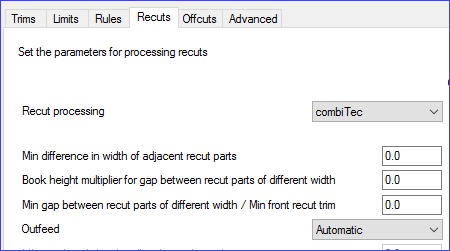

These other methods process the recuts as part of the rip cycle but this typically reduces the range of recuts that can be taken. The options for these other methods and related parameters are found on the 'Recuts' tab under 'Optimising parameters'. (Main screen - Parameters - Optimising parameters - Select list - Recuts tab)

Use the 'Recut processing' option to select the type of process; this also highlights the extra parameters that apply to the method chosen. The options are:-

Saw

combiTec

Recut device

Select the method required using the list box

Select the method required using the list box

Different recut parameters apply for each mode. Those not required are greyed out.

Saw

This is the 'standard' and most flexible method as it allows for more multiple recuts. Recuts are usually taken after ripping and crosscutting are complete. No extra parameters are needed for this; use the 'Recut settings' Optimising parameter to set the level of recuts.

| See: Recut settings |

combiTec

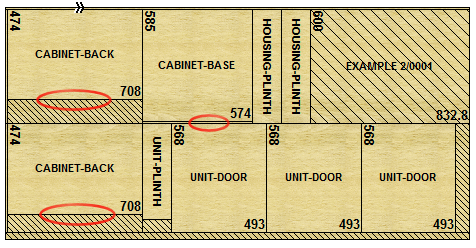

Any single recuts are sorted into a staggered pattern (from narrow to wide) in the strip. The rip saw can take the recuts before the strip is crosscut. Typically extra space is included between the parts with recuts so that the saw is able to make the complete cut without damaging the adjacent part. Saw models (21, 22, 25).

See: combiTec |

Recut device

Recuts are taken with a recut device that is separate from the saw. These recuts are made before the strip is crosscut and this applies only to single recuts.

| See: Other recut devices |

|

|