Generate cutting patterns from a list of part sizes

The program optimises part lists to produce cost effective cutting patterns.

● Enter a part list (or import from an external system, or create from an order for products)

● Optimise

● Review cutting patterns and summaries (also called runs or optimisations)

● Send cutting data to a saw (or machining centre)

Access all these options from the Main screen.

Before Optimising a part list it is essential to set up a BOARD LIBRARY to describe the materials (boards) and to create at least one set of OPTIMISING and SAW PARAMETERS to describe cutting methods and the saw. Examples are provided in the demo data installed with the program.

After optimising view the Cutting patterns and Summaries on screen using 'Review Runs'.

When satisfied with the Cutting patterns these can be optionally transferred to the Saw or Machining centre

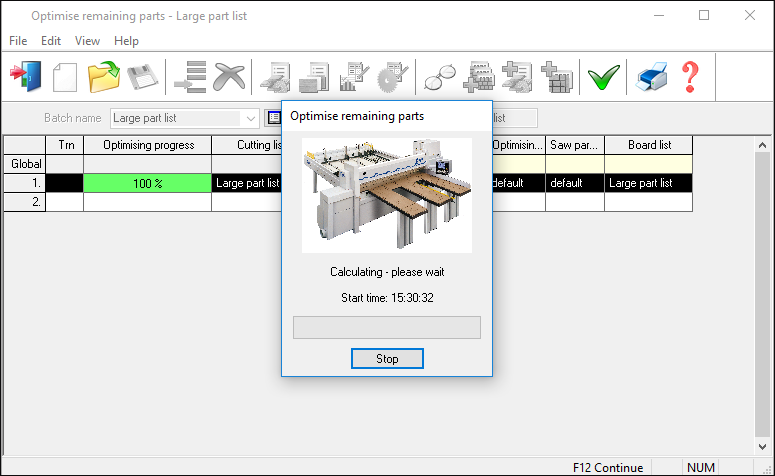

During optimisation

Optimising progress is shown on the screen.

[ Stop ] - halt the optimisation

The program prompts to store the results so far or to abandon the results.

Overall progress is shown in the 'Optimisation' dialog and progress for each run is shown by a colour in the grid. For example green indicates a completed run and blue a run underway.

If there is an error with a run or with part of a run the program prompts

with an error. In some cases it is possible to continue and the parts

that cannot be optimised (e.g. not enough material) are ignored. For more

serious errors the Continue button is greyed

out and the optimisation does not proceed. Check the part list, board

list and parameters to locate the problem and correct it

If there is an error with a run or with part of a run the program prompts

with an error. In some cases it is possible to continue and the parts

that cannot be optimised (e.g. not enough material) are ignored. For more

serious errors the Continue button is greyed

out and the optimisation does not proceed. Check the part list, board

list and parameters to locate the problem and correct it

See: