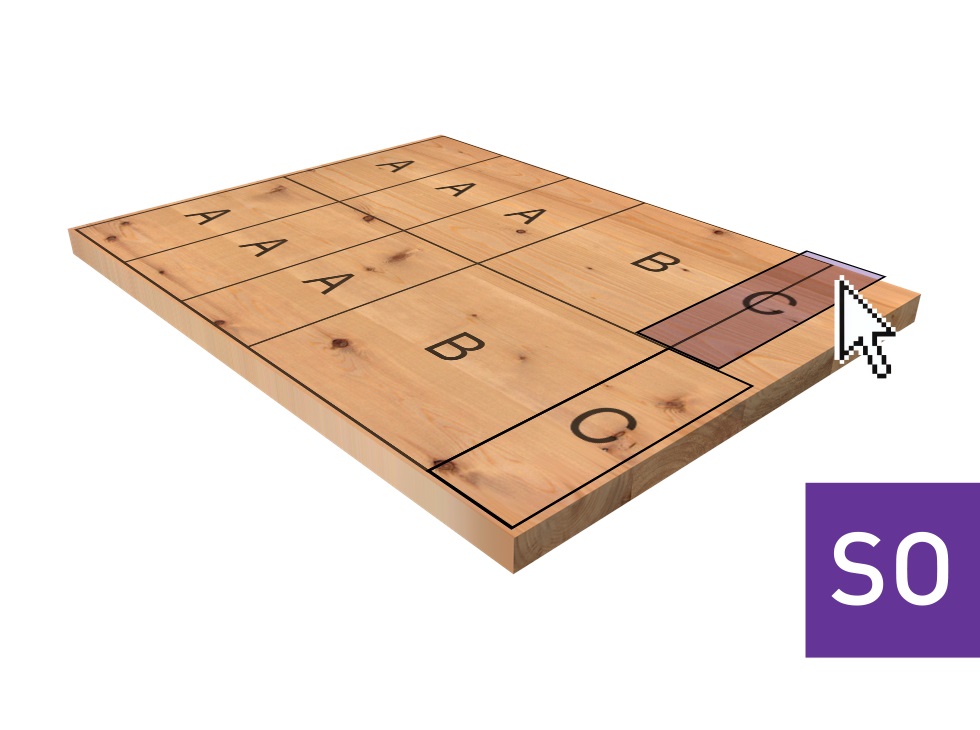

Standard Optimiser

The Standard Optimiser is the entry level for Magi-Cut Modular, and is designed for cutting batches of jobs on a single axis beam saw, where both material usage and cutting time need to be kept to a minimum.

With the use of the machining centre interface a fully integrated system can be created, whereby parts produced at the saw can be labelled with a barcode. Once the part drawing has been downloaded to the machining centre the barcode can be scanned guaranteeing the part is machined correctly.

Edging, Machining, Pattern Amendment, Forms and Labels, Saw Interface and the Parts library are included as standard.

Highlights

- Part lists (jobs) may contain up to 10,000 pieces - mixed materials - grain/cross grain or non-grained parts - metric or imperial sizes - required and plus/over parts.

- Up to 99 user-defined fields of information per part including edging material can be entered or imported directly from spreadsheets.

- Cutting list rules based on user defined tables - numeric & string formulae - allows automatic cutting list adjustments ready for optimisation.

- Integrated board library - holds material specifications, sheet sizes, cost, available stock, automatically records offcuts for later use.

- Extensive optimising and saw parameters with integrated help allows precise control of cutting patterns and these may be overridden by material specific settings.

- Grain matching - Position parts in defined templates within the cutting pattern to achieve a uniform veneer pattern.

- High speed optimisation with multi-core processors; multiple jobs (up to 250) can be optimised in one batch. Minimum material cost with practical cutting plans.

- Reports include management summary, material usage, cutting time, offcuts, costs, parts produced, waste% by pattern, weights.

- Calculation of cutting time based on extensive saw settings and job costing summary showing full breakdown of production costs.

- Configurable summaries, allowing choice of columns, fonts, subtotals with option for graphs and bar charts for management reporting.

- Pattern display - thumbnail preview - show material texture or colour coding for recut parts and offcuts.

Ease of integration

We switched to Magi-Cut almost two years ago to coincide with a new beam saw. We are extremely pleased with Magi-Cut and especially the ease of integration and technical help in the original setup. We have no hesitation in recommending the software which has run without a hitch since the original installation

Tim Martin- Waterford Kitchens

Printer friendly info